Understand Wool by Understanding Super Numbers

In the world of suiting, wool is, without a doubt, a favored fabric, and among the many varieties of wool, worsted wool is one of the most popular. Worsted wool encompasses a wide array of fabric types and qualities, and one of the simplest ways to classify worsted wool is by its “super number.”

You may have seen the term super number appear on retail websites or in fabric swatch books, usually in the context of phrases like “super 120s” or “super 180s.” But what do these numbers, and the designation of “super,” actually mean?

Today’s video will thoroughly explain what a super number is and the impact that it has on garments made from super-graded fabric. We will also explain the origins of the super number system and trace its development alongside the expansion of the larger worsted wool industry.

Defining Worsted

“Worsted” Can Have Different Meanings in Different Contexts

Technically, the term “worsted” could describe three different materials.

Combed Yarn

Yarn made from wool fibers that have been rotated by metal combs to align the long fibers while discarding short staple fibers can be called “worsted.”

Yarn Weight

A number of hanks, a unit of measurement, of yarn, each with a length of 560 yards, that weigh one pound, is called a “Worsted Weight.”

Fabric

Any 100% wool fabric that is made from a combed worsted wool yarn can, in its finished form, be referred to as “worsted.”

Why Combing Matters

Combing produces a long-lasting, fine, and smooth yarn with a somewhat glossy finish. By adjusting the pull of combs on the wool, one can get lighter or heavier yarns, whereas varying the twists will impact the look, feel, and strength of the yarn. Tight twisting provides a crisper feel, whereas loose twisting makes for a softer but weaker yarn.

Defining Super Number

Super numbers represent the fineness of the worsted wool fiber used in the fabric. The higher the number, such as Super 100s, 120s, or 150s, the finer the wool thread is. The actual number is calculated by the maximum number of hanks of wool that can be spun into one pound of wool. For example, if you can spin 100 hanks each 560 yards long, the resulting wool is classified as Super 100s.

Is lighter worsted wool better than a heavier weight?

The answer is not necessarily, no. Let’s take an overcoat as an example of this principle; while a softer fabric would feel more pleasant on one’s skin, a heavier coat made of something like Donegal tweed is going to be much more sturdy and keep you warmer than a lighter and softer cashmere coat would. Of course, you’re not often going to be wearing an overcoat against your bare skin but this illustrates the principle that the heavier weight is going to be sturdier than the lighter weight even if the lighter weight is softer.

Is lighter worsted wool cooler than a heavier weight?

While you might be under the impression that a lighter weight weave is going to be cooler to wear and a heavier weight would be warmer, this isn’t always the case. Something that’s heavy but relatively open in its weave like a fresco fabric, for instance, is going to feel much cooler when worn than something that’s tightly woven and lighter like a super 150s fabric, for instance.

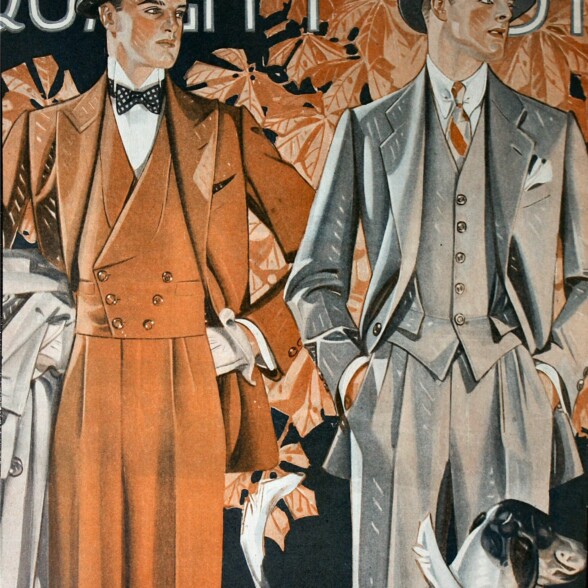

Vintage fabrics were simply

Heavier

Fabrics available today are usually going to be lighter in general than fabrics that were produced even 30 or 40 years ago. This will be readily apparent to you if you visit a thrift store and pick out an old suit: it will usually feel noticeably heavier. Modern manufacturers have adopted lighter fabric weights to cut costs, even though heavier weights improve durability and drape.

The Realities of High Super Numbers

We hope that we have made it clear that a lighter fabric with a higher super number is not a hallmark of better fabric: it simply indicates the fibers used were thinner in diameter. Similarly, the super number doesn’t provide any information about the weave or how heavy the fabric is.

How Super Numbers Were Developed

The Origins of Worsted Wool: Two Rams and Four Ewes

You might be surprised to learn that the wool used to manufacture many suits globally comes from sheep that are descended from just two rams and four ewes.

In 1789, King Carlos IV of Spain gifted six sheep to the Dutch East India Company; these sheep were then shipped to South Africa. In 1795, a British immigrant to Australia named John McArthur bought 26 of the offspring of these original six sheep and transported them back to Botany Bay, Australia.

These 26 sheep were then bred to form the backbone of what is now the Australian wool industry, with sheep that now number more than one hundred and twenty million.

The Super Number of

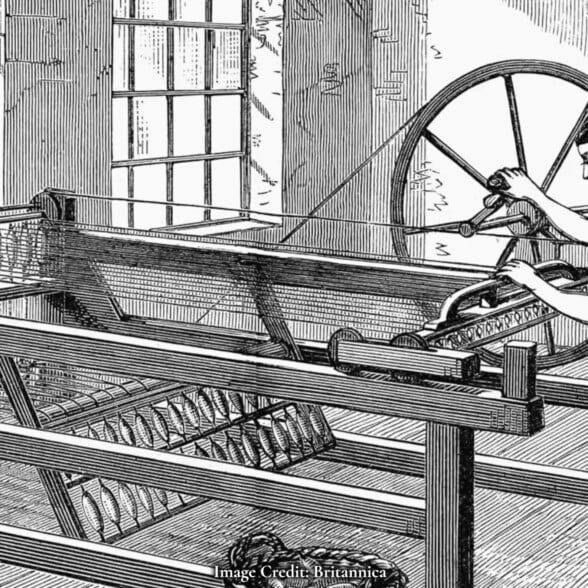

Historic Wool

In the early 19th century, wool mill production processes were still in their infancy, as was the breeding of sheep to produce fine wools. As a result, super numbers of between 60s and 80s were considered superlative for their time, and 100s was thought unattainable. Therefore, what has been considered “fine” wool throughout history has always been a relative term.

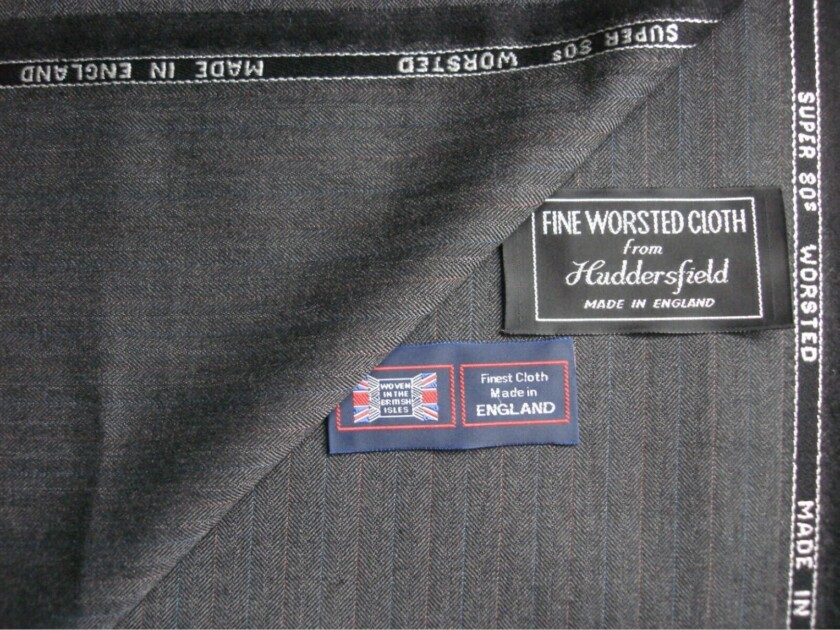

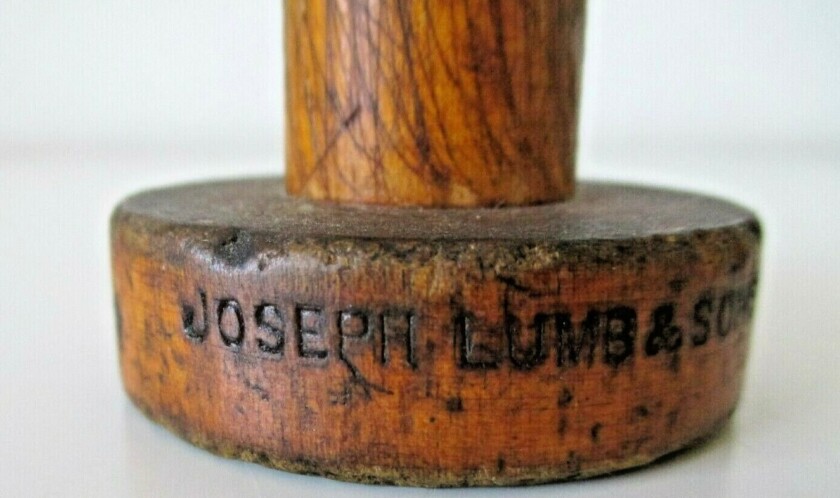

New Techniques Produce Superior Wool at English Mills

The first 100s-grade worsted wool was manufactured in England by Joseph Lumb and Sons, of Huddersfield, West Yorkshire. Lumb bought enough of this wool for an entire year’s supply and brought it to market under the name “Lumb’s Huddersfield super 100s.” Thus, the “super” terminology for worsted wool suits was born.

At this time, British wool merchants would often refer to their wares by largely subjective terminology in describing how fine the wool was, employing terms like low, medium, fine, the newly created super, and so on. These relative terms, however, differed from maker to maker.

Standardizing Methods for Grading Wool

Because producers and consumers eventually wanted terminology that was more objective in how the wool was rated, the city of Bradford, England led the way in grading wool more objectively. This process became known as the English worsted yarn count system or, more generally, the Bradford System, also known as the Bradford Count.

Fast forward to 1968, when the USDA created the United States standards for grading wool, assigning ranges of average fiber diameter, or AFD, and maximum standard deviation to the previously established Bradford Count.

The finest manufacturers will voluntarily comport their wool with the highest standards set by the International Wool Textile Organization, or IWTO, to establish their offerings as quality products on the international market.

There is still an element of

Subjectivity

Over the years, some companies have gotten a little subjective in exactly how they’re grading their super wools. So, for example, a super 200s wool from one manufacturer might be a bit different in how fine it is from a super 200s wool from another manufacturer. On the whole, however, the differences are minimal as international standards still have to be respected.

Super Number FAQ

What is worsted wool?

Worsted wool refers to a type of wool that has been combed to ensure that the fibers are parallel, resulting in a smooth and fine yarn. This process creates a firmer and more durable fabric which often presents a cleaner, more polished appearance.

What are worsted wool super numbers?

Worsted wool super numbers represent the fineness of the wool fiber used in the fabric. The higher the number, such as Super 100s, 120s, or 150s, the finer and lighter the wool thread is.

How is the ‘Super’ number determined?

The ‘Super’ number refers to the maximum number of hanks (a unit of yarn measurement) of wool that can be spun into one pound of wool. For example, if you can spin 100 hanks each 560 yards long, then the wool is classified as Super 100s.

Does a higher super number mean better quality?

Not necessarily. A higher super number indicates a finer thread which can create a smoother and lighter fabric. However, durability might decrease with higher super numbers, making them less suitable for everyday wear.

Are higher super numbers more expensive?

Yes, generally, the higher the super number, the more expensive the fabric since they require finer wool fibers and a more delicate production process.

How should I care for my worsted wool garments?

Wool garments should be dry-cleaned to preserve their shape and texture. Avoid frequent washing and opt for spot cleaning whenever possible. Use a proper hanger to keep the garment’s structure.

Can worsted wool be worn year-round?

Worsted wool suits are versatile and can be worn year-round. Whether a fabric has a low or high super number, an open weave will be more breathable and, therefore, more suitable to warm weather, while a closed weave will be more insulating and suited to colder weather.

Where does the best worsted wool come from?

Some of the most highly regarded worsted wools originate from Australia and New Zealand due to their high quality and consistency. However, excellent quality worsted wools are produced in other parts of the world as well.

What Super Numbers Mean Today

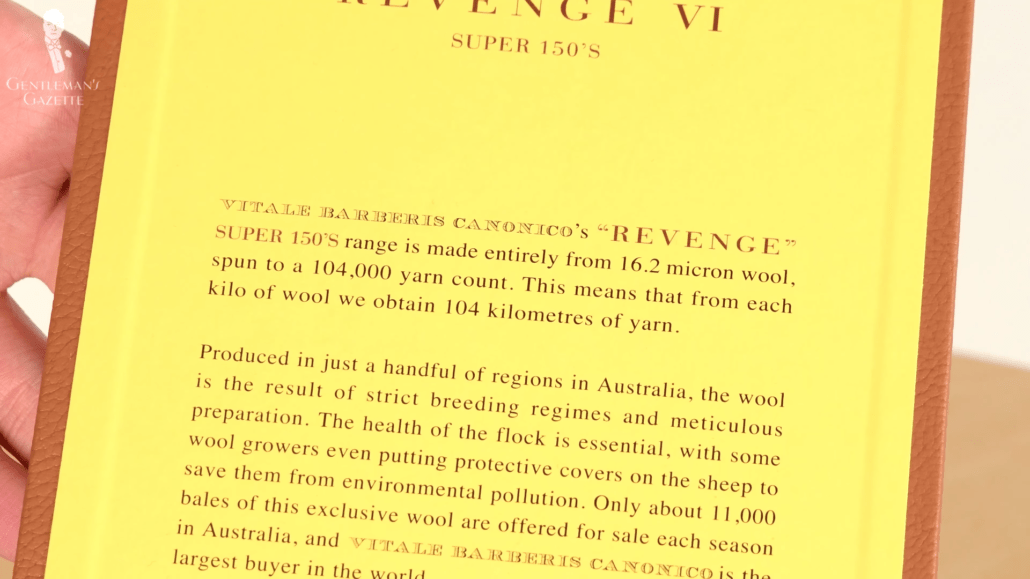

Today, super numbers measure how fine a piece of wool is by effectively measuring how many times each of the individual woolen yarns have been twisted around. Generally, then, the higher the super number is, the finer the cloth in question will be. Often, this means it will also be lighter, but as we said earlier, this isn’t always the case. How fine these woolen yarns are is typically measured in micrometers, also called microns.

| Super “S” Numbers | Maximum Fiber Diameter |

|---|---|

| SUPER 80’s | 19.75 µ |

| SUPER 90’s | 19.25 µ |

| SUPER 100’s | 18.75 µ |

| SUPER 110’s | 18.25 µ |

| SUPER 120’s | 17.75 µ |

| SUPER 130’s | 17.25 µ |

| SUPER 140’s | 16.75 µ |

| SUPER 150’s | 16.25 µ |

| SUPER 160’s | 15.75 µ |

| SUPER 170’s | 15.25 µ |

| SUPER 180’s | 14.75 µ |

| SUPER 190’s | 14.25 µ |

| SUPER 200’s | 13.75 µ |

| SUPER 210’s | 13.25 µ |

| SUPER 220’s | 12.75 µ |

| SUPER 230’s | 12.25 µ |

| SUPER 240’s | 11.75 µ |

| SUPER 250’s | 11.25 µ |

| SUPER 260’s | 10.75 µ |

As a result, a higher super number will mean that a fabric is going to be softer to the touch and generally will feel more luxurious. Conversely, a lower super number will mean that the cloth is more sturdy and probably warmer. As we’ve said, it will generally be heavier, but not always.

Super Number is Unrelated to

Thread Count

While it is commonly believed that the super number of a given fabric also has something to do with its individual thread count, this isn’t true and there is no correlation between the two measurements. Super number refers to the fineness of a yarn while thread count is a measure of the number of threads woven into one square inch of fabric.

While a higher super number does, to some extent, denote the exclusivity of a given fabric, because something like a super 200s would contain some of the rarest wool fibers available, this is only an indication of that exclusivity and rarity, not necessarily subjective quality.

Can you call that “super?”

According to international convention, the word “super” can only be applied to fabrics made of new, pure wool. Fabrics made from wool blended with other fabrics like cashmere, alpaca, silk, or the like can use the related “S” designation but not the full word “Super.”

Super Numbers and Your Wearing Experience

A Higher Number Is Not Always Better

It is often assumed that a higher super number will always equate to a better wearing experience, but this is not necessarily the case. In fact, you must take into consideration formality, practical concerns, and your needs to determine what level of super number is right for you.

Stated simply, anything with a higher super number is going to be more temperamental and harder to care for over time. The thinner, finer fibers of a wool with a high super number may have an amazing hand, which is to say, how soft they feel to the touch, but they’re also going to break down much more quickly than a heftier fiber would.

Something like a super 180s wool would probably feel softer on the body, whereas something like a super 100s wool is going to be more durable, less prone to wrinkling, and probably better suited for repeated everyday wear.

For instance, snags in finer fabrics happen much more frequently and are also far more difficult to repair than a snag in a comparatively coarse fabric.

What Super Number is Right for You? It depends!

Raphael says …

“Speaking generally, it’s our opinion that it’s best not to get overly caught up in the super numbers of your worsted wool suits. Very good quality suits can be created from wool in the super 100s to super 150s range and even below that, and of course, a suit which is well fitted to the wearer’s body is going to look great regardless of what the super number might be or even if it doesn’t have one. Conversely, something in a super 180s or super 220s wool is still going to look sloppy if it doesn’t fit your frame well.”

Super Number Quick Tips

To close this guide, we have prepared a few general guidelines for you on how to consider the super numbers of your suits and how to wear them effectively.

Lower is Better for Everyday Wear

For standard everyday wear, you should consider a fabric with a pretty low super number. Consider something that’s below 100s up to a super 100s or super 120s, for example.

Consider Higher Super Numbers for Important Events

For an important business meeting, a conference, or something that’s a bit more important than the average day-to-day at the office, you could consider a super 130s or super 150s fabric.

The Finest Fabrics are for the Finest Occasions

For very special occasions or more formal events, a very high super number, such as super 180s or higher, makes sense, as you are unlikely to wear the garments often so they are unlikely to suffer regular wear.

Fit is the Most Important Consideration

Whether wearing a low super number wool, a high super number wool, or a wool made from any material, fit is the most important consideration.

Conclusion

While the super number of a worsted wool can be handy in determining how fine and soft the yarns of a given wool are, it should not be used as the only measure of quality in wool suiting. Remember to focus first on fit, then determine if you really like the look of the suit and how often you think you will wear it. If these points are agreeable to you, you can then consider the super number as a factor.

Do you have a preferred super number? Let us know in the comments!

Outfit Rundown

While Preston is wearing a wool suit, the fabric on this garment does not have a super grade, illustrating that a suit doesn’t need to be “super” to look super. It is charcoal in color with a slightly tufted texture. Although part of a 3-piece suit set, Preston rarely wears the accompanying waistcoat.

Preston’s pastel pink shirt is from Charles Tyrwhitt, and he emphasizes this elegant color with platinum-plated eagle claw cufflinks grasping carnelian balls, a Prince-of-Wales check tie with a subtle burgundy hue, and his miniature pink carnation boutonniere, all made by Fort Belvedere. A white linen Fort Belvedere pocket square provides a clean point of visual interest for his front.

On his feet, Preston is wearing a pair of black leather captoe derbies. For a simple transition from his trousers to his shoes, Preston’s socks are solid charcoal gray.

Thank you, very enlighting as always!

I just bought a jacket (Corneliani Trend) that combines Hemp with Wool (75/25). Would welcome your thoughts on this combination as it is new to me. One to keep, or better change for different fabric?

Thanks!

Peter

Great article. I do some tailoring in my spare time, and I prefer worsteds below Super 120 as they are easier to shape. Because they are typically a little heavier, they drape better, which is more flattering to the wearer.

How does the term “tropical wool” fit into the issue of super numbers, if at all?

Tropical is a general designation of the intended wearing situation, and the weight. Historically, “tropical “ worsteds were 9 oz., or less, usually plain weaves, frescoes, or bengalenes/bengalines. The openness of the weave, and the hard finished yarns allowed air to flow more freely (often said, “they breathe better”). They were intended for warmer climes.

One crucial factor not mentioned here, is yarn ply. Purveyors of cheap cloth and clothing often promote the “Super number”, but fail to note their cloths are singles. Higher numbered cloths, which are only single ply, are delicate and prone to both wear issues, and severe wrinkling. Combine that with the fact that far too many purveyors of menswear think the numerical designation refers to yarn/thread count, and you have a disaster born of ignorance. Any quality cloth, at minimum, should be two ply in the warp, and ideally, 2×2.

So very helpful, great work. Many Thanks!

It is our pleasure! :)