While menswear is not immune to the natural evolution and cyclical nature of the fashion industry and its trends, there are a few wardrobe essentials that have endured the test of time and are actually reaping the benefits of a revivalist movement, based upon the gentlemen of old. The recent burst of interest in the sartorial universe and a renewed love for classic aesthetics, techniques and tradition has enabled men to become more aware of their image and personal style, catapulting menswear essentials to a never before seen level of recognition and demand.

Shirts, in particular, have never enjoyed such popularity and importance in a man’s attire as nowadays; whereas suits, jackets, overcoats and shoes have always held a predominant place in a primary canvas, shirts were often overlooked as background, a complement to the full look. With the current re-evaluation of the value of a perfect dress shirt, it seemed only appropriate to dedicate a post to an exhaustive look at what truly makes a quality dress shirt.

Fabrics

Although fabrics are the core element of a high-quality shirt, the purpose of this guide is to point out those small details that go into the construction of a premium dress shirt and set it apart from the average market offerings. Still fabric quality can’t be overlooked. It is immediately perceived by the wearer, and top-notch construction is easily overshadowed by a low-quality fabric, while a higher-end fabric is usually enough to leave low-quality technical details unnoticed. For more information on shirt fabrics please take a look at our shirt fabric guide and the Albini videos.

Alternatives: Bespoke, Made to Measure or Ready to Wear

In an ideal world, every style enthusiast would wear nothing but bespoke garments, but the truth is having custom pieces made is not an option for everyone. The beauty of shirts is that you are able to find premium-quality MTM options, with fabrics in the 100/2 range starting at about $150, which is reasonable compared to off-the-rack shirts of similar fabric.

Within the MTM universe, you can either consider finding an experienced tailor or seamstress, able to craft an entirely handmade version, or opt for industrial or semi-industrial alternatives. In this guide, I will not focus on artisanal details of entirely handmade shirts because there are so many techniques and variations that it would be a never-ending article. Instead, we will focus on general hallmarks of quality in shirt construction.

Of course, many ready-to-wear labels offer great workmanship and if you have a standard figure, you are all set. However, most people don’t, and so custom shirts are the way to go.

Construction

If you allow me, I would kindly ask you to pick one of your favorite shirts from your wardrobe (preferably one with a pattern) and have it handy while you read this article; ask yourself why you like it and what makes it so special. Take a look at it: collar, cuffs, yoke, stitching, buttons, side seams, gussets, armholes, hemline, the works… Chances are you notice some details you were unaware of until right now, right?

So, let’s take a closer look at the shirt starting from the top.

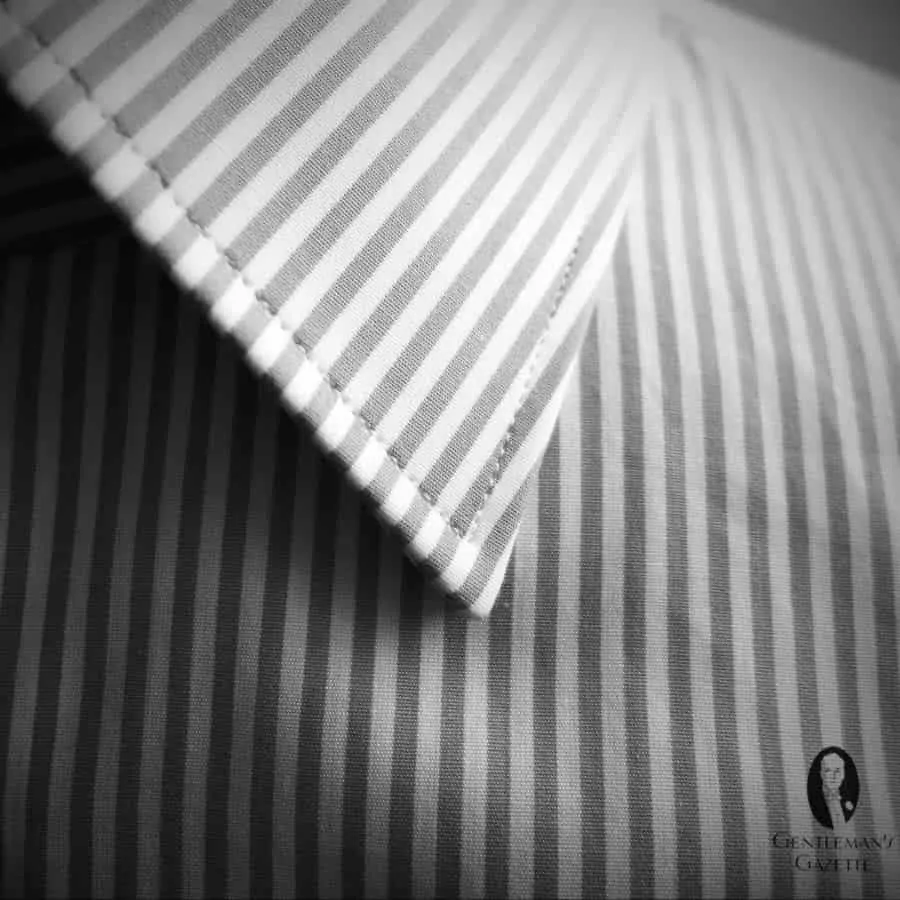

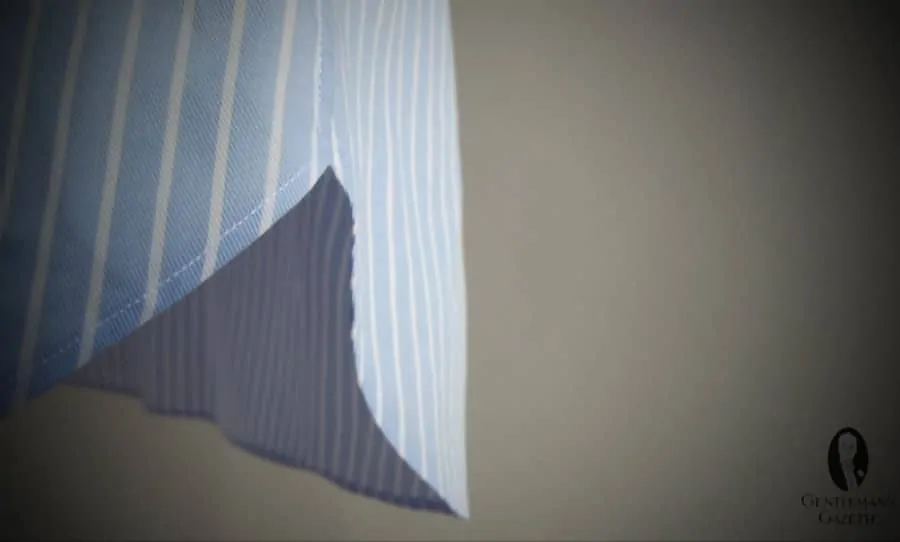

1. Fabric Pattern Matching

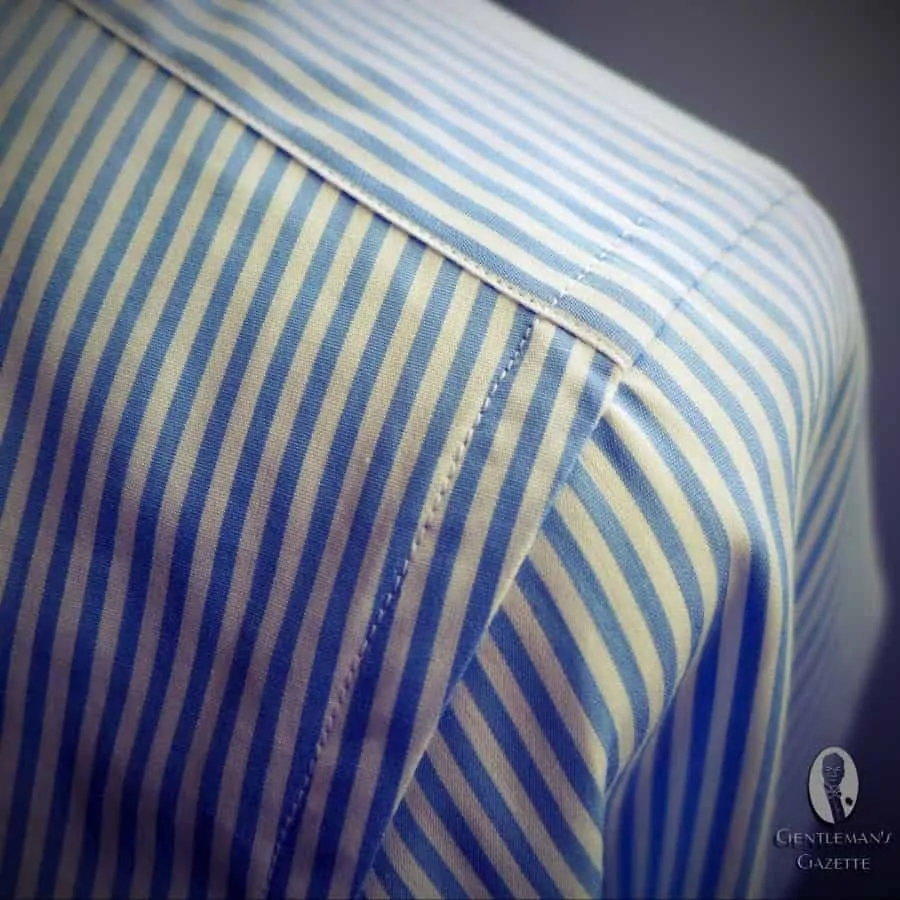

An easy way to check the quality of a shirt is how well the pattern of a checked shirts is lined up at a few critical seams. If it is well done, then you will likely find all the other hallmarks of a good shirt as well. The following areas should be matched perfectly:

- shoulder to sleeve

- pocket (if is has any)

- split yoke

- sleeve to sleeve placket

- shirt fronts and front placket

- Of course you can match the pattern on the side seams as well, though this is not seen very often

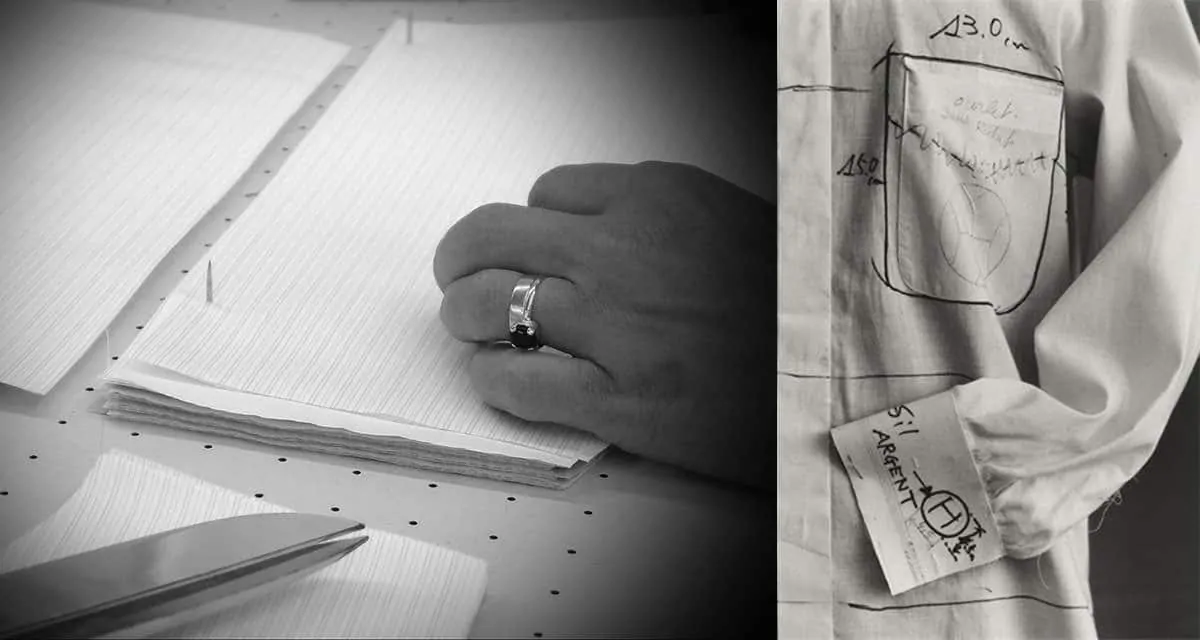

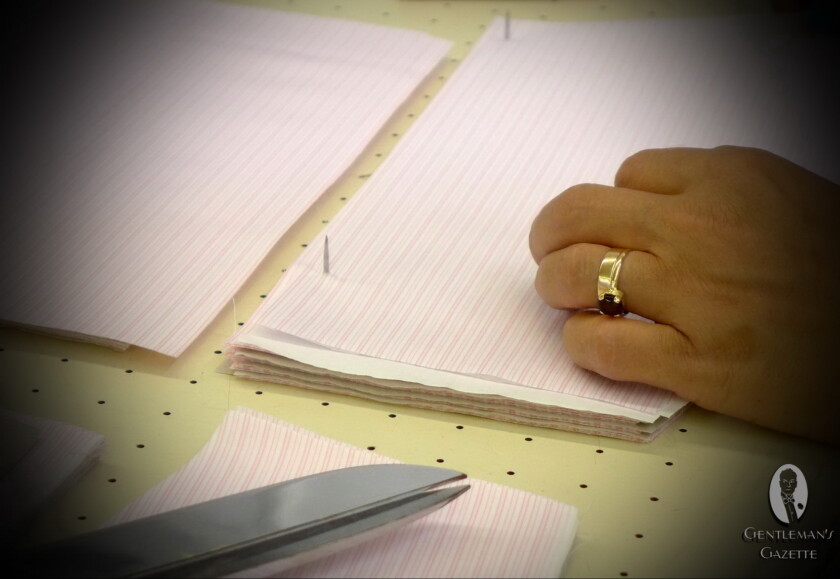

Matching the fabric pattern in all these areas demands great skill of the manufacturer and hence it is usually only achieved by experienced professionals, who know how to assemble a shirt with the utmost skill, care and attention. Most shirtmakers use needle tables, where each shirt component is aligned individually and placed one by one on top of the other, to achieve this kind of perfection. Of course, if you opt for folded shirred shirt sleeves on your sleevehead (aka spalla con grinze), it is impossible to match the pattern perfectly.

2. Pattern Development

Once you have a shirt that fits you perfectly, you expect the same fit and workmanship for all future shirts. However, as you might have experienced yourself, consistency is not always a priority of lower end labels. Even for experienced hands, it is very difficult to produce the exact same fit over and over again because high end shirt manufacturing requires so many manual step and humans do things a little differently every time. The more steps in the shirt making process that are done by hand, the higher the chance a shirt will be inconsistent at the end. At the same time, handmade details provide a shirt with a unique feel and beauty that’s unmatched.

In order to deliver the best of both worlds, most quality shirt manufacturers rely on carefully developed patterns that are used every time that particular model is produced. Body patterns are usually cut from thick paper, whereas collars and cuffs are sometimes made out of metal to ensure absolute accuracy.

For custom shirts, it is important to have a skilled shirtmaker or tailor take the measurements, and to take note of the physique of the wearer. Ideally, he should take pictures of the person from the front, back, and both sides while the customer is not wearing a dress shirt, to understand the unique properties of each customer’s body. Only if these intricacies are correctly translated to the shirt pattern, will you be able to enjoy a well-fitting shirt at the end of the process.

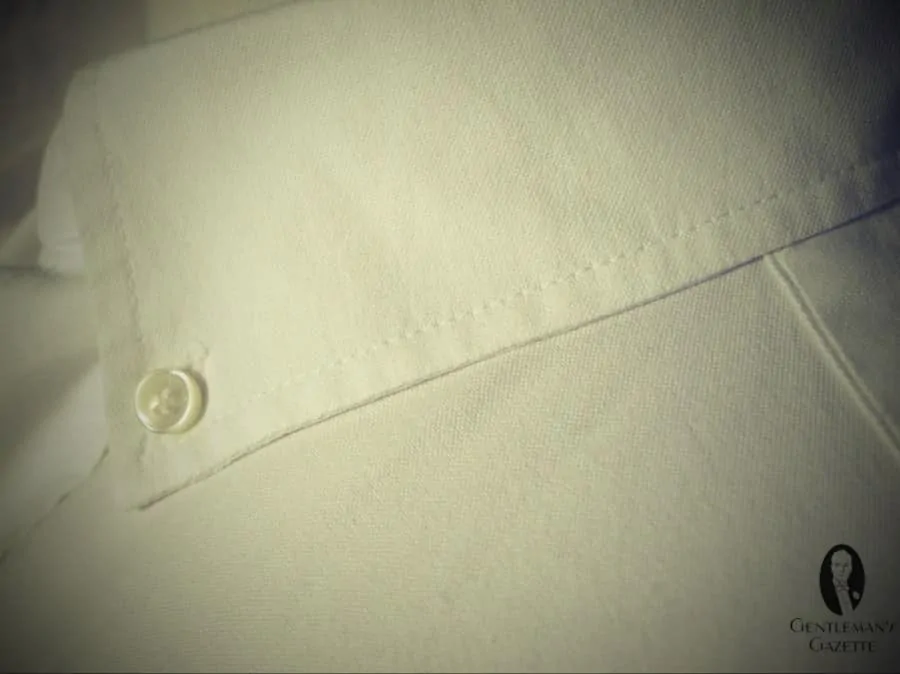

3. Stitching

Stitch density, as well as consistency, are a good way to judge the workmanship of a shirt. Tightly woven fabric should have a very high density of stitches, which results in an elegant look and durability. Very delicate open weave shirts sometimes require slightly larger stitches in order not to destroy the fabric but if that’s the case, your shirtmaker knows about that.

For custom shirts, you can also determine how far away you want the stitching from the edge. Most classic shirts feature 8mm stitches, while formal tuxedo shirts sometimes only have 1mm or 2mm stitches to create a more elegant look. As a rule of thumb, whatever you choose, ensure that the top-stitching on your collar and the cuff are the same, otherwise it looks unfavorable.

In Italy, high end shirt often feature decorative hand pick stitching along the seams. While this does not add to the durability of the shirt, it certainly can look very nice.

4. Side Seams

Traditionally side seams can be finished either with twin-needle or single-needle stitching. Higher-end shirts will always use single-needle because it provides a cleaner look and dressier appearance, making it perfect for dress shirts (it is also more difficult to produce). Twin-needle stitching is commonly found on more relaxed or casual shirts and is easily recognized by two rows of stitches running along the side. Due to the different materials of thread and fabric, the area between the needle stitches will wrinkle heavily after a few washed, which is why every dress shirt should have single-needle stitching.

5. Collar

The collar is the most striking feature on a shirt, and is usually visible at all times. Therefore, it is crucial to choose the right style for your face and wardrobe. For custom shirts, there are almost endless variations and some MTM manufacturers offer the deviate from their standard collars to get you exactly what you want. There is no right or wrong in regard to collar styles, but whatever you choose, it should be a well-made collar.

The first thing you should pay attention to in a collar is the type of interlining used and whether it is fused or non-fused. Collars are generally made from two pieces of fabric: top and bottom, with some interlining in between. These layers can either be held together by heating and gluing them (fused) or simply by sewing them together (non-fused). As with fabrics, collar interlinings are available in different weights, which result in different stiffness or softness.

Now, most shirts today are fused because it is less expensive. The majority of fused collars today are cheaply made and of poor quality. Therefore, many high-end shirtmakers will advertise their unfused collars because they require more skill and cost more. Generally, they are soft and many men today seem to like that. However, there are high-quality fused collars that provide a crisp collar for a different look. For example, evening shirts or more formal white shirts will likely look better with crisp, fused collars whereas casual shirts should features non-fused, soft collars. A complete wardrobe should contain shirts with fused and non-fused collars so you can choose the right one for the occasion.

In any case, it is worth mentioning that sewn collars require extra attention when it comes to maintenance (especially ironing). If you are not skilled, the collar will end up with small wrinkles, which simply looks bad. Furthermore, the trademark natural look that is usually accompanied by subtle wrinkles may not please everyone.

Another aspect to take into account is the perfect symmetry between collar points: both ends should sit exactly at the same distance from the center of the collar — this is easily perceived on a striped shirt, for instance, where the two points should sit exactly over the same stripe.

When ordering a custom shirt, you can also choose the tie space, so your tie knot will look great. For example if you wear Windsor knots, then you should have some tie space, whereas a four-in-hand knot doesn’t require any tie space.

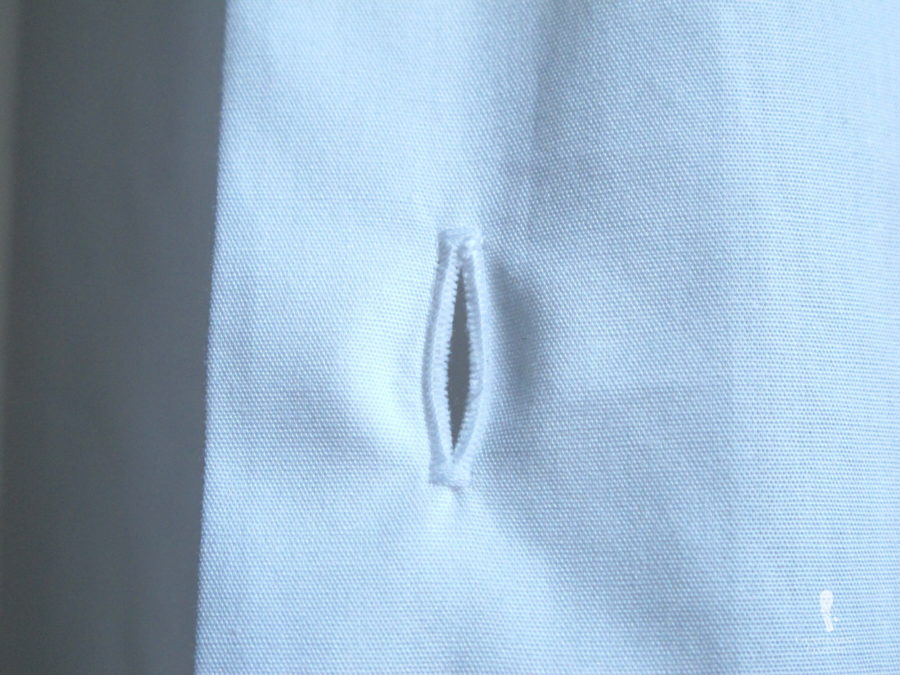

6. Yoke

The yoke is the back part of the shirt that connects neck and shoulders and may assume a variety of shapes and patterns depending on the shirt model. Commonly, the yoke is made of one piece of fabric. However, on custom shirts, it makes sense to have a split yoke so the varying degree of your sloped shoulders can be accommodated correctly. Also, a split-back yoke can help to match the shirt pattern on the sleevehead. A split yoke is also often used on higher end RTW shirts, but since they are symmetrical, the impact is limited.

7. Trimmings

Besides fabrics and construction, there are other elements that are also invaluable to a shirt’s aesthetic and that are usually overlooked as mere accessories. Trimmings play a huge role in the outcome of a luxury shirt, be it the quality and shine on the stitching yarns, the beauty of the buttons or even the choice and quality of the interlinings.

For dress shirt buttons, mother-of-pearl is the standard worldwide. Of course, like with so many things, there are various qualities of mother of pearl, with the better ones featuring a more beautiful luster. You can quickly determine if it is mother of pearl by touching it with some metal (your iron). Alternatively, you can touch it with your tongue – if it feels cold it is mother of pearl.

For casual shirts, corozo or horn buttons are good alternatives, whereas plastic buttons simply look cheap. Some people prefer flat buttons, which are easier to button but more prone to break, while other try to use the thickest buttons they can get their hand on.

In any case, the top button on your collar should always be slim be cause it really facilitated buttoning your shirt and you will wear out your top buttonhole much more slowly than if you have a 4- or 5mm-thick collar button. For interlinings, the best come from Germany or Switzerland and your shirtmaker should always be able to tell you who supplies them and what options you have.

8. Ascolite Thread

Few things are as annoying as losing one’s shirt buttons. High-quality shirts usually feature buttons that are sewn on by hand with a shank. The extra space between button and shirt fabric is important because there will be two layers of cloth when its buttoned and without a shank you will see centric wrinkles around every button. However, the excessive use of laundry detergent and general wear and tear can weaken the thread and sooner or later some of your buttons will fall off.

In recent years, the company Ascolite developed an extremely resistant and elastic thread, that is ideal for attaching all kinds of buttons and prevents them from falling off. This detail is usually not found at bespoke tailors but only a few high-end shirtmakers. Below, you can see how it is done.

9. Sleeves

An important feature of shirts are the sleeves and the way they are sewn to the shirt. Most of the time, the sleeves are sewn on in the process of sewing the entire shirt together. This is less expensive and the sleeves rarely hang perfectly. Also it can feel constricting to the wearer. Ideally, the shirt sleeve should be sewn on at the very end, so they are rotated to the prefect position for the wearer. This is a detail hardly any shirt manufacturer offers.

When you look at the area of the armpit most shirts will match the side seam with the sleeve seam which is not ideal and indication that they weren’t set in properly. If these two seems don’t match, they were set in at the end of the process, and chances are they drape better with fewer wrinkles and the shirt is more comfortable to wear.

Especially in Italy, some gentlemen prefer the sleevehead of their shirt to feature little pleats. While is not a hallmark of quality per se, but rather a matter of taste, it surely requires more handwork and is hence more expensive to make.

10. Monograms

Monograms have become very popular even with low-end Made-to-Measure providers and haberdashers. Unfortunately, people don’t think about the history of monograms and add them in various places in all kinds of colors. Traditionally, gentlemen only wore white shirts and often changed many times a day. In order to keep the shirts separated in the laundry, they had tone-in-tine monograms on the waistband or inside the collar, so you’d hardly ever see them.

Today, people sometimes choose to have their monogram put on the chest pocket or even worse the cuff or collar. This is rather tasteless and hence you should have your monograms just above the natural waist, or in a place where it can’t be seen too often. Luxury shirts often offer the option of having an entirely hand-embroidered monogram, which is the epitome of skilled artisans and are harder and harder to find nowadays.

It goes without saying that shirts should never feature any visible logos on the chest.

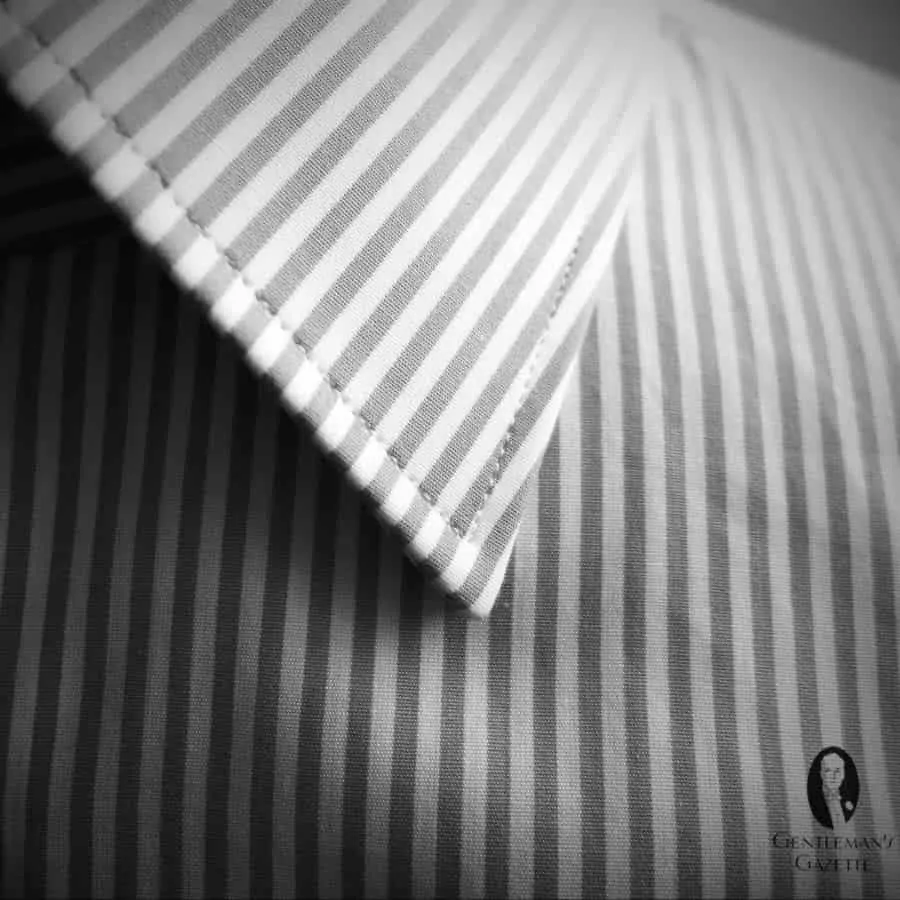

11. Buttonholes

Ideally, a buttonhole should be cut first and then sewn. Many lower-end shirt buttonholes are sewn first and then cut. Although this is less expensive, it leaves ugly threads behind. Traditionally, buttonholes were hand-sewn and there are great differences in terms of the stitch density and gimp thread used on custom shirts. Many Italian high-end RTW shirts feature hand-sewn buttonholes as well because they are more expensive to produce.

However, machine-made buttonholes that are cut first and then sewn with a high stitch density can be very beautiful as well. In regard to longevity, machine-made buttonholes will likely last longer, while handmade ones are a tribute to craftsmanship. At the end of the day, it comes down to personal preference, although I would always prefer a nice machine made buttonhole over a mediocre handmade one.

The lowest button of the front placket is usually horizontal because it leaves more room for expansion which is particularly important in this area when you sit down. Sometimes, people also claim that the horizontal buttonhole on the sleeve placket should be horizontal on quality shirts. While it require more accuracy to have a horizontal buttonhole that can be buttoned, there is not much extension needed in this area, which is why I would not pay too much attention to it.

12. Gussets

Some claim that gussets are a necessary part of a quality shirt, but in fact it is as difficult to produce a neat sideseam without one. Personally, I don’t mind a gusset but I don’t consider it a must-have feature on a quality dress shirt.

13. Cuffs

Basically all you need to know about cuffs has already been explain in our Sleeve Length Guide.

14. Video Example

In order to better understand how a shirt is actually made, you can watch this video:

Conclusion

Shirts have come a long way since they evolved from an undergarment, and today they are often worn as a statement piece in their own right. If you want a quality shirt these guidelines should help you to weed out shirts of inferior quality. Especially in Italy, there seems to be an obsession with entirely handmade shirts, and while I can appreciate the craftsmanship and attention to detail, such as hand pick stitching along all seams, it is not a requirement of a quality shirt. In fact, most of it does not add to the longevity of the shirt but is merely for looks. But then again, we dress for beauty and not for function alone.

What criteria do you look at if you determine the quality of a shirt? Please let us know in the comments.

Peruse Our Ultimate Shirt Guide!

Great article! I make shirts for myself, and I use only sew-in interlinings (like canvas) for collars and cuffs.

Good article but written from most perspective of basis good quality shirts and not the finest shirts but I assume its intentional. For example, the depth of pattern matching for us goes way beyond the areas mentioned and the areas mentioned are more elementary.

Probably it would be nice if you would look/ review one of our shirts. There are not many who can make a shirt like this.

Have a pleasant day

Akshat

Great discussion. However, given the plethora of quality RTW shirts. There really is no reason to buy MTM or bespoke shirts unless you want something unusual such as detachable collars. Keep up the good work.

As one who principally buys RTW, I am forced to agree.

Hmm, I think the pictures and the article make it very clear why there is such a thing like bespoke shirts.

Thanks a lot for this enriching guide. I wouldn’t know any better and more detailed advice than what can be found here. Again I know, why this fine gazette stands out in its kind.

Greetings from across the Atlantic.

Thanks Gernot.

Oh dear, now I will have to take a second look at my wardrobe, carefully suss out my shirt collection and see which ones require passing on to my local charity shop. I enjoy lovely clothes, and usually hold onto them for several years, or even decades.

For this reason, I buy only the best I can afford, and pay particular attention to the best style of shirt that will suit more than one outfit.

I generally buy RTW, which on a clergyman’s pension is the best one can do!

Well, fit is the most important thing. Though once you have a well fitting shirt with details you like, you’ll notice that you wear it a lot more than all your others.

Great article – however, one thing that you have not mentioned is a slightly larger cuff on your watch wearing wrist. My tailor always asks me: 1. will I be wearing a watch with the shirt; and 2. which wrist do I wear said watch (albeit he now only asks me question one, as he now knows which wrist I wear my watch). The larger cuff will (naturally) comfortably accommodate your watch.

That’s only something for MTM and bespoke shirt and it will be covered in another article.

As a garment worn next to the skin and upper part of the body which turns, rotates and moves the most during the course of the day, I believe the shirt is even more critical to one’s comfort than the jacket or even trousers, so very well written.

Personally I wear bespoke shirts exclusively which run in excess of 150, I suspect or may be 200 … I don’t know and wouldn’t want to know :-)

Greetings,

indeed another very informative article you have certainly provide me with additional insight when it comes to acquiring MTM shirts.

In fact several months back I had the opportunity to read one of your reviews on MTM shirts and since then I have actually had a few MTM shirts prepare for me by Modern Tailors and have come to really appreciate the enormous difference between RTW shirts as oppose to MTM shirts.

In addition to the outstanding quality MTM shirts since I do all my own personal laundry of my dress shirts I find that MTM shirts have an impeccable finish after each ironing.

I just want to request that in your follow up article if you can please share some specifics e.g. fabric blends 100% cotton verses 70/30 ratio and shed some light on shirt fabric weight e.g. 80 ply verses 120 ply pros and cons.

But all-in-all Mr. Schneider truly an outstanding article!

Regards,

P J Weatherby

Dear P.J. we already discussed in our shirt fabric article which is linked above.

As one who works with men & their style I really appreciate the education your blog affords. Including the wisdom and consideration given to quality, what that is exactly and why it’s important. I am also grateful to hear about the history of the various types of clothing.

I am grateful for the ongoing revival of *The Gentleman* as a whole and expectantly look forward to the overall enlightening of the male species in terms of their style and personal consideration of their physical presence. ;)

Look forward to more excellent articles! Thank you

What a terrific article. I make my own shirts, and I’m glad to see someone else is obsessive about piecing as I am (e.g., sleeve to yoke pattern matching; sleeve placket matching to sleeve field stripes; front placket pattern matching to field stripe, etc.). I absolutely obsess over these details *validation*. One thing I had never heard of, was the offset of the sleeve seam and the side seam. This was very interesting.

I am glad you could learn something!