Business pundits are fond of complaining that the British economy is unbalanced: the services industries are too dominant, while manufacturing has been in a slow, seemingly irreversible decline ever since the sun set on the Empire.

Whether this thumbnail sketch of the British economy is at all accurate is perhaps a moot point, but if there is any such trend, I have just met two men who are travelling very successfully in completely the opposite direction: Tony Gaziano and Dean Girling, who in 2006 set up Gaziano & Girling, Northamptonshire’s first new shoe manufacturing company in over 100 years.

After decades which saw a remorseless decline in British shoemaking (and of so many other manifestations of British industry), the uninformed observer might be justified in wondering about the wisdom of such a scheme.

No one should under-estimate the potential hazards that await anyone whose ambition is to start a new manufacturing enterprise. Nevertheless, a cool appraisal of matters suggests that Dean and Tony’s daring venture has various matters in its favour. High-end shoemaking is enjoying something of a renaissance at present, for one thing, and both men come from the bespoke end of the trade – Cleverley, Lobb, Edward Green – where reputation is of paramount importance. Well-connected within the trade, they have been able to attract a dedicated team of talented craftspeople. And crucially, both are gifted craftsmen and designers with a distinctive aesthetic vision.

The Philosophy

Situated in a quiet street on the outskirts of Kettering, Gaziano & Girling’s factory is quite small. In fact that is an under-statement – it is extremely cramped, the operations seemingly at imminent risk of spilling out onto the street. I soon learn, however, that new, much larger premises are being made ready to move into.

For the present, however, I am led through the bespoke and finishing room, which is bedecked in time-honoured fashion with customers’ lasts, to a corridor that seems almost blocked by shoe boxes, finally gaining entry to the office of Tony Gaziano and Dean Girling. With less than a month to go before their North American trunk show, they must be extremely busy men, yet they have been generous to a fault in finding time to meet me.

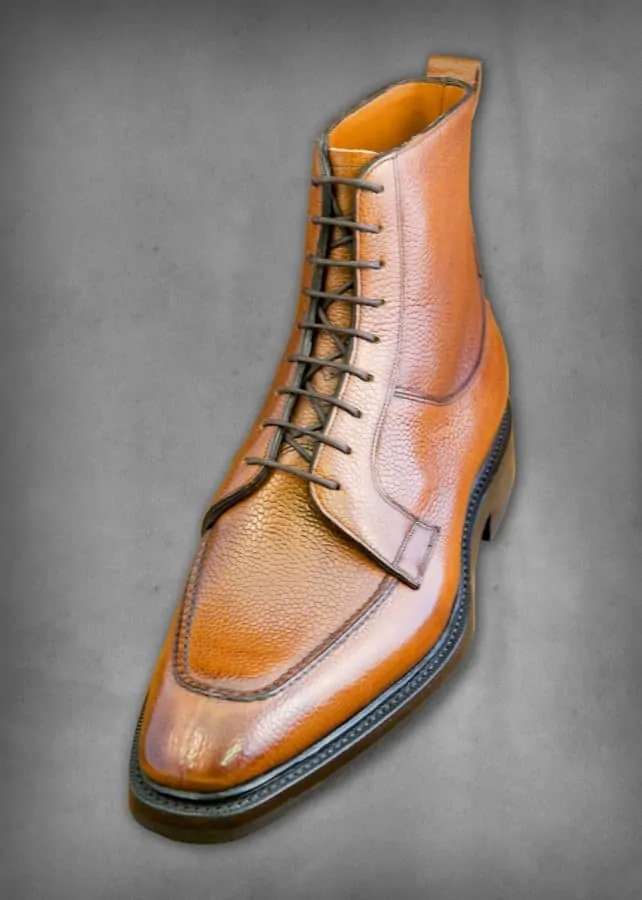

Bespoke lasts in the finishing department Perhaps not typical of G&G’s oeuvre, but I liked these country grain boots very much

There must be upwards of 200 different sample shoes lining the office. I am keen to look at these more closely, while meanwhile Tony and Dean talk about their vision for the company, which in a nutshell is to endow their RTW shoes with the level of attention to design detail that was formerly the sole preserve of bespoke footwear – applying the much wider palette of bespoke colours, leathers, flourishes, shapes and attention to detail, while eliminating that suggestion of excessive conservatism that can be detected in some English footwear. Melded with the strength and integrity of English construction there is an Italian elegance and sophistication, yet these design flourishes are not such as to draw undue attention to a man’s feet.

Before and after St Ives – Vintage Cedar & Ivory Suede – Side

We then talk about cars for a while – as my eye takes in the shoes’ quite rakish, angular shapes and gleaming, glossy curves, I think about E-type Jaguars, but then wonder if the Ferrari is not a more apposite simile. Dean says their shoes have top-of-the-range Bentley and Aston Martin qualities; he mentions some of the other well-known high-end brands, which he compares to BMWs and Mercedes – well-made, high-quality; yet lacking that extra input of craftsmanship and sophistication necessary to lift things into a special bracket of luxury and desirability. I ask whether they see these other firms as rivals. Without exactly saying as much, the sense is conveyed to me that Gaziano & Girling are without rival. Edward Green, John Lobb and Alfred Sargent perhaps come closest.

Gaziano & Girling Shoes

Gaziano & Girling’s bench-made shoes are all made using traditional techniques and the finest leathers, from France, Switzerland and Germany. Sole leather is among the best in the world, from J. & F.J. Baker & Co Ltd in Devon, where it is oak-tanned for 12 months in 2,000-year-old tanning pits that were constructed by the Romans, giving it superior strength and durability.

The shoe shape is refined and elegant, with an accentuated waist. The waist shape under the arch is highly pared back; handling the shoe (in this case an Adelaide semi-brogue, chosen at random), I see that the shape of the waist is not only elegant but also likely to be highly supportive to the arch of the foot. The welt is nicely bevelled, while within the waist it is pared almost flush with the upper up to the junction of the welt and the heel; the heels are pitched inwards.

A channelled welt. the leather flap will be glued down G&G’s characteristic sole with fiddleback waist This is a trial shoe

The uppers are very finely sewn, and great care has been taken in the design and finish, such that the lines seem to flow through the shoe harmoniously – the downward curve of the vamp, for instance, coincides exactly with the position of the heel, and so on. Turning the shoe over, I find – as might be expected – that it has a channelled welt, and there is a prominent fiddleback to the waist.

Then I am handed one of their bespoke shoes, of quite similar appearance, although here the vamp is of suede. At first glance the two shoes seem to be of equivalent construction, but closer inspection reveals that the stitching of the bespoke shoe is finer still. But one would have to be quite wilfully pernickety to find fault with the bench-made shoe – which, for shoes costing up to $ 1300 / £800 is just as well. Obviously with bespoke, the customer’s options are almost limitless, but with prices starting at around $4,850 / £3,000, and up to 12 months from consultation to wearing, you have to be quite sure that bench-made is really not for you.

Contrasts abound Bespoke lasts and a trial shoe Bespoke lasts being shaped

The support of an existing body of bespoke clients was crucial to the founding of Gaziano & Girling. Wealthy clients attach great importance not only to the superior quality of their footwear but also to the comfort of their feet – the level of trust between client and bespoke shoemaker must perhaps be something akin to that between a patient and his trusted physician.

At present, the firm makes 80–100 pairs of bench-made shoes a week. At 100–150 pairs a year, bespoke remains a small yet important part of the total output, and is a crucial element of the firm’s identity. One imagines a gentle drip-feed of bespoke suggestions filtering down into the bench-made collection.

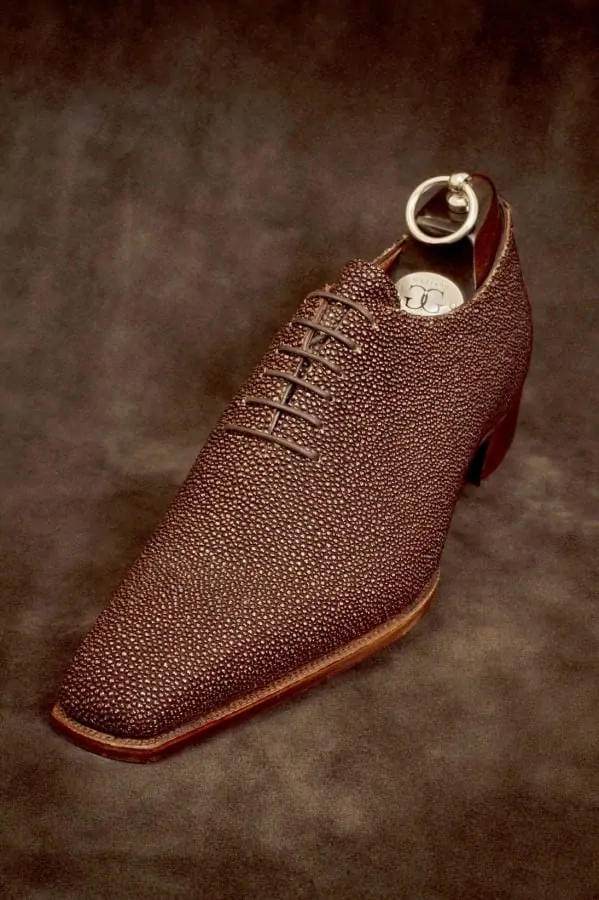

Falling between bespoke and bench-made, there is made-to-order, giving the customer a wide choice of specifications ranging from style, last shape, width, leather and colour, to sole. Personally I cannot imagine choosing any sole other than leather at this level, but rubber, in the form of Dainite or Wensum, is available. As an example of MTO, I was handed a shoe from the distinctive Deco line, which can be made using alligator, stingray or other exotic hides. The shape of the sole and waist is even more distinctive (a ‘spade waist’) than the earlier shoes I had examined.

A bespoke stingray-skin shoe An alligator-skin shoe from the Deco collection

For purposes of comparison, a venerable John Lobb is brought out, a highly polished old black brogue that has clearly seen some service over the years – it reminds me a little of the Prince of Wales’ well-worn shoes. This makes an interesting comparison – the Lobb is finely sewn and precisely put together, yet blunter and somehow a little fussy-looking, next to the G&G. It is beautifully constructed, yet one somehow feels less thought has gone into the design. It is when comparing the waists that the comparison seems most unfair to the Lobb – it is broad-of-beam, flat-footed and frankly fallen-arched (but perhaps its owner was?), compared to the more streamlined, sculpted, paired-down and fiddlebacked G&G. The Lobb’s heels are pitched slightly outwards, which as Dean points out is incorrect.

I look at more shoes – there is a really impressive range of styles on display here, considering how short a time the company has been established. There are some lovely contrasts of calf and suede, country calf and hatched grain, besides stingray and alligator on display. Some styles verge on the formal and discreet, while others display a more exuberant character. Some of the colours are stunning – not in an exhibitionist sense, of shouting for attention, but rather just very well chosen and tasteful, pleasing to look at. I could spend all day examining the shoes here, but time is passing and we have a factory tour to make.

The welting and soling machines Welting Glueing down the channelled welt

Conditions are quite cramped, with insufficient storage, while in terms of the efficient flow of materials, the factory layout leaves much to be desired. Confined spaces are not always conducive to good humour, but I form the impression that the workforce seem happy. Earlier, Dean had emphasised to me the depth of tradition among the company’s workforce – compared to Northampton, Kettering has as much if not more heritage as a shoe town, and many of the workers are sons and daughters of shoemakers, so are more properly seen as craftsmen and skilled specialists, rather than factory workers.

Setting up a functioning shoe factory from scratch can have been no easy undertaking – the machinery necessary for lasting, welt-sewing and soling is no longer manufactured locally, and had to be acquired second-hand or refurbished from various sources. It is old, but in good condition – made to last, haha. Interestingly, the lasting machine is of the same design as that used by Edward Green, who had been under the impression that theirs was the only one of its type still in use.

In the clicking area, I’m shown rolls of calf leather from Germany. Here, uppers are being cut out which will be hand-sewn to make apron-fronted derbies. Some of this work is sent out at the moment, as far afield as Skegness on the Lincolnshire coast.

Space is tight in the old factory Soling

Gradually we work our way back to the bespoke last-making and finishing room, where I watch a last being filed to shape, and Dean explains the bespoke process in detail to me. As one would expect, precise measurements and other requirements are taken, at the company’s Savile Row showroom or at a trunk show in North America or the Far East. An over-sized last is then pared down to precise form, and a dummy shoe is made for the customer to try on. A note of any necessary alterations is made and the last is adjusted accordingly, on which the shoes are subsequently made. Naturally, lasts are all kept for future orders (Dean says they probably lose money on the initial order).

Dean then offers to show me Gaziano & Girling’s new factory, a few streets away. Formerly one of Loake’s factories, it backs onto another shoe factory, one of Church’s outlying establishments. It had lain idle for a few years but was now in the final stages of a refurbishment programme, ready for occupation very soon. The new factory is roughly three times the size of the old one, and besides being efficiently laid out, will have dedicated and purpose-built areas for design and bespoke work, as well as better office facilities and room for a showroom and storage and despatch areas. The mezzanine office has a wall of windows overlooking the factory area, which itself is well illuminated from north-facing roof lights. Everything seemed spacious and well thought-out, and one can only envisage this dramatic improvement in the firm’s physical accommodation as forming part of an overall scheme of expansion.

Bigger, better, more employees, a new shop in London’s Mayfair opening in December – I’m no business guru, but I do get the feeling this company is going places. Dean Girling and Tony Gaziano are to be congratulated for the forceful way in which they have pursued their ambition of revitalising high-end shoe-making – in their own terms, striving to make Gaziano & Girling ‘the sine qua non of classic male elegance’. They are making luxurious and expensive shoes to sell to well-off and highly demanding customers – and doing so successfully, it seems.

Isham – Espresso Calf – Side Hove – Vintage Oak – Side Wiltshire – Vintage Cedar Burnham – Vintage Oak

There is no need to be sniffy about catering to this market – perhaps one can even see the Gaziano & Girling model as a novel way of turning the tide in our nation’s commerce? In a post-industrial world in which the only Englishmen making real money are bankers, hedge-fund managers, City lawyers and Premiership football players, setting up a factory making highly crafted luxury shoes – or other luxury goods – to sell to all those millionaire bankers and lawyers … surely that has to be the way to go? Only joking, but it’s a thought.

Where to buy Gaziano & Girling Shoes

Factory/Bespoke Workshop

Gaziano & Girling Ltd

Masefield Works

Hallwood Road

Kettering

Northamptonshire

NN16 9RG

England

Email: [email protected]

Phone: +44 (0) 1536 511022

London Showroom

12 Savile Row (Lower Floor)

London

W1S 3PQ

United Kingdom

By Appointment only

Bespoke Email: [email protected]

Made to Order Email: [email protected]

Phone: +44 (0) 1603 434949

North America

New York

Leffot

10 Christopher Street (corner of Gay Street)

New York, NY 10014

(212) 989-4577

[email protected]

Barney’s

660 Madison Ave

Manhattan, New York

+1 212-826-8900

Bergdorf’s

754 5th Ave, New York

+1 212-753-7300

San Francisco

Wilkes Bashford

450 Stanford Shopping Ctr

Palo Alto CA 94309

650 322-7080

Khakis of Carmel

Carmel Plaza, Ocean Ave, Carmel, CA 93923

+1 831-625-8106

Toronto

Leatherfoot

24 Bellair Street (Yorkville)

Toronto, Ontario

M5R 2C7

Tel: 1-855-967- FOOT (3668)

I congratulate G & G and wish them the best. They make a beautiful shoe. I have two pair which I recently purchased from Barneys.

Establishing a new brand in a crowded field is no easy task.

My only words to G & G are “keep-on plugging!”

Mark E. Seitelman

http://www.seitelman.com

I truly can not wait until I can afford to splurge on shoes as beautiful as these. A college man can dream! Thanks for continuing to introduce me to fine brands as such.

Steven P

You’re welcome