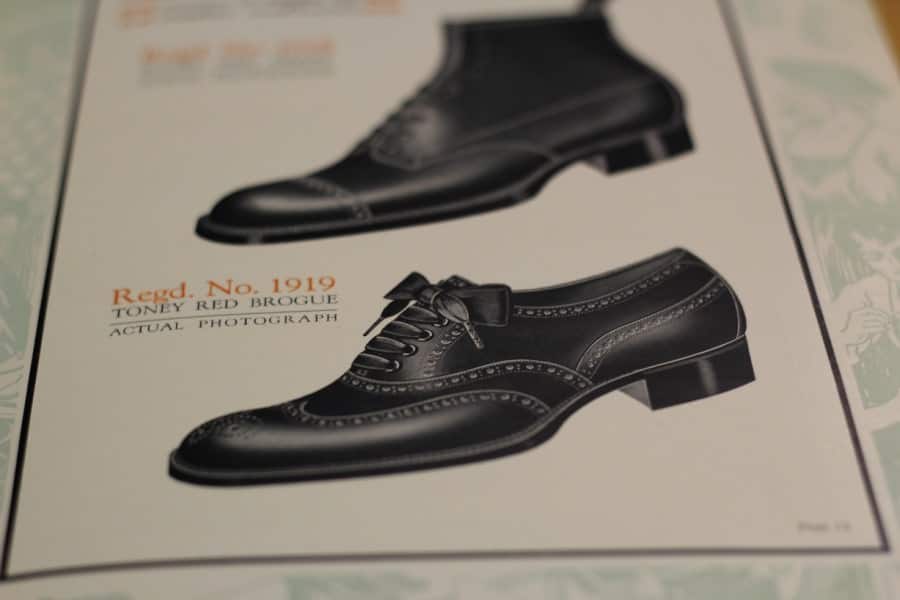

“Very good shoes – with a twist … we push the boundaries” – that’s the motto of Sanders Shoes, and with this coverage we would like start a series about shoe manufacturers and take you on a journey through the Sanders & Sanders factory showing you what makes these shoes so special. A 1920s shoe factory in Rushden – a quiet and down-to-earth English Midlands town – may seem an unlikely destination if you are Eric Clapton, but indeed that is where he has his crocodile-skin shoes made. Nor is he alone in his quest for suitable footwear – others who have made this pilgrimage include a Japanese gentleman, who visits twice yearly, and American designer Mark McNairy; those who can’t come to the factory, buy them online.

Northampton Shoe History

Just as California’s Silicon Valley and Hollywood are synonymous with particular industries, so an unusual feature of England’s industrial landscape at one time was the concentration of certain industries in various localities, and not always for any obvious reason: Luton – famous for hats; Stoke-on-Trent – porcelain and ceramics; Leicester – hosiery; Nottingham – lace; and so on. Northampton became known for shoes from around the time of the Civil War (the outcome of which, according to some sources, was decided at the Battle of Naseby by 500 parliamentarian shoemakers from Northampton, whose sudden arrival proved sufficient to turn the tide of war against King Charles and the Cavalier cause).

Northampton’s tradition of shoemaking derives from its richly verdant rolling landscape, well suited to bovine agriculture, and the formerly abundant oak forests and willow plantations along the River Nene, giving rise to a leather tanning industry and hence to the production of shoes.

War, in particular the First and Second World Wars, kept Northamptonshire’s shoemakers extremely busy producing all manner of military footwear – marching boots, flying boots, officers’ boots, cavalry boots, desert boots, even felt-soled boots for munitions workers – all made in Northampton for service from Rangoon to Bermuda, from Cape Town to Spitzbergen.

The post-war loss of captive overseas markets, and an influx of cheaply manufactured imports, spelt doom for many of the Northampton shoemakers. Those few that have survived, however (without exception, the survivors are the upmarket and higher-quality makers) have in recent years experienced something of a renaissance, regaining a foothold in overseas markets that are newly appreciative of quality and tradition, and benefiting to some extent from the advent of internet shopping. Undeniably, a part of the appeal is simply that the shoes are Northampton-made, on Northampton lasts – they have the prestige of tradition. Yet some makers are moving production offshore – risking the loss of that mantle of tradition, some would say; concentrating on core values of design and marketing while benefiting from the opportunities of globalization.

It may be a matter of rather arcane interest, but there remains a residual distinction in Northamptonshire between the Northampton-based “town” shoe factories – such as Tricker’s, Church’s, Crockett & Jones – and the “county” shoe factories such as Loake, Alfred Sargent, and Grenson, located further down the Nene valley. My visit today was up-country: destination Rushden, to visit the rejuvenated and evidently flourishing firm of Sanders & Sanders Ltd.

Sanders Shoes

Hitherto one of the lesser-known English shoe firms, Sanders is a family-owned company now into its fourth generation of Sanders. Their MD, Henry Sanders, has masterminded a doubling of turnover in only three years, and Sanders’ workforce has gone from working three-day weeks to flat-out overtime in an effort to keep up with orders. At present they make 1,900 pairs a week, a total which is increasing monthly. Their strategy has combined a determination to retain all production in England with respect for the firm’s traditional emphasis on production values and attention to detail, and a bold approach to design details, exploiting the firm’s heritage.

Besides selling under their own brand, Sanders devise bespoke designs for Mark McNairy and others – roughly half their production finds its market in this way. During my tour of the factory I came across a batch of particularly nice long-wing brogues being made for an American brand. The pebble-grain shoes were distinguished by the addition of a (slightly frivolous) red, white and blue heel-pull ribbon. Some of Sanders’ own-brand shoes also sport such heel-pulls, but in a more sober Brigade of Guards colorway.

Another relatively recent but important area of sales is Japan. The firm has delved into its rich archive of military footwear designs, now being reproduced in fine detail on lasts modified to suit the Japanese foot. Browsing Sanders’ military-inspired Japanese website, my eye was drawn to one shoe in particular, serial number 9252, a stoutly made army grain black brogued ghillie shoe, which gave me pause for thought, my mind probing the improbable: my flight of fancy brought on visions of Scots battalions – whole regiments even – kilted, sporraned, bagpiped, armed and ready to die fighting for the Emperor of Japan.

Sanders Factory Tour

I was conducted on my tour by Simon Tennant, Sanders’ export sales manager. He took me first to the design studio, where specifications and patterns are worked up, and then to the hide storage, where rolled-up hides, in a great range of colours and textures, lay intermixed with bolts of tweed, canvas and other fabrics. Unrolling a box calf hide recently delivered from a French tannery, Simon explained that advances in animal husbandry mean that calfskins are now significantly larger than just a few generations ago. Even so, demand for fine leather is such that prices are rising all the time.

Survival of the Fittest?

Questioned about the reasons behind the survival of the remaining shoemakers, Simon’s answer was rather dismissive: “Survival is not really the word to use. The county and the town’s shoe manufacturers are flourishing … the factories are busy – the ones who are still manufacturing in the UK. A lot of the brands, because of price, have had to have the product made offshore. We make everything here – everything for our export markets, our UK market, is made here, under one roof.” The factory is quite family-oriented – skills have been passed down from father to son, mother to daughter, over several generations in some cases.

Leather

Given the expense of calf leather, clicking – the job of cutting out the different parts of the shoe upper – is clearly a task requiring much skill and experience, both to accommodate any natural blemishes in the skin, and to use the hide in the most efficient and economical way. Clicking is accomplished either by hand – cutting around a set of brass-bound templates – or with the use of a vast press and precision dies. I watched vamps for brogues being cut in this way – the medallion and all the perforations are cut in a matter of seconds, rather than, as I had somewhat naively imagined, with pinking shears and a hole punch.

Uppers

Moving on, the uppers are assembled stage by stage by a team of highly skilled women, each one seemingly dedicated to a single specialist task, until eventually – eyeletted and embryonically formed – the uppers lie stacked in trolleys, row upon row, awaiting removal to the lasting room.

Lasting

Ear-plugs to hand, we move from the subdued domesticity of the sewing room to the ruggedly masculine lasting room, where the air is rent by metal machine noise and the smell of heavy adhesives cooking somewhere. Amidst a seeming maelstrom of activity, the operators commune with a battery of machines so complex and machine-gun noisy that the eye cannot easily discern their function – machines that seem a tad reminiscent of the work of H.R. Giger. In the end, the workers produce a top quality, goodyear welted shoe.

Shoe in the Making

The final transformation of hides into high-quality foot coverings is completed quite swiftly, in a process of deft exchanges between men and machinery as first the uppers are tacked to lasts, then united with footbeds, welts, heels and soles. There are numerous pains-taking stages of careful detailing – extraneous sole material is ground away, then the sole-edges are dyed, burnished, polished, transformed to a perfect smooth finish. The sole itself is scoured, polished, then decorated with the characteristic bunking – a traditional signifier of attention to detail. The shoes are later moved into a calm oasis, the finishing room, where final polishings, inspections, approval and boxing-up takes place.

Sanders own the Regent brand, an exclusively equestrian line of footwear that is produced alongside yet marketed separately from the Sanders brand. The Pro Cotswold is a classic English riding boot; a variant of it is standard issue for every mounted police officer in Britain. Regent offer other classic equestrian styles too, such as the strapped jodhpur boot and the elastic-sided jodhpur, and even lightweight jockey’s boots.

Applying decorative markings on the sole, known as bunking. This is the traditional style of Wellington boot and will be familiar to officers of British cavalry regiments, being standard footwear for formal occasions. There is a spur box within the heel block.

To watch how a Sanders & Sanders shoe is made, take a look yourself:

Where to buy Sanders?

Sanders shoes are available at the likes of Paul Stuart and Barneys in New York, various places in England and online at Pediwear.

Sanders = Variety

Because of the batch production process, only a limited range of models were passing through the production line during the time of my visit. Nevertheless, besides affording occasional glimpses of the eclectic vision at work within Sanders’ design team, there were ample indications of the great depth of the firm’s involvement in footwear – in addition to the aforementioned brogues, I saw loafers, suede chukka boots in various colours, riding boots, jodhpur boots, boots for mounted police, motorcycle boots, pebble-grained bluchers, crepe-soled brothel-creepers, a variety of regimental and military footwear, shoes with blue soles, shoes with red soles, and some low-cut boots which combined Prince of Wales check suiting with pebble-grain broguing.

What makes Sanders so special?

I ask Simon what he thinks Sanders do that is different.

“Our look is very strong. You’ve got Crockett & Jones, Church, you’ve got Edward Green – the classic shoe people, and they make fantastic shoes. Sanders make very good shoes too – but with a twist … we push the boundaries of shoemaking with regard to flexibility and construction.”

A “twist” was undeniably there in many of the designs I saw; bold colours here and there, unexpected contrasts of textures, welting and sole colour, as a counterpoint to restrained conservatism in other areas of design. What struck me was that there was something in each design that still seemed to represent something of an archetype – indeed, sometimes falling only just short of a caricature – the most rugged brogue, the most louche chukka, the most oxford. In every respect, the materials and methods of construction seemed such as to inspire complete confidence in their longevity. Bold colours, contrasting soles, and chunky shapes are the signature of many of Sanders’ designs.

Website: www.sanders-uk.com

Mr. Long,

indeed a very timely and insightful information about the manufacturing of a quality made shoes, as I read your article I simply imagine how the shoe cobbler’s of old went about crafting their work with such intricate care and design for me it is always amazing to see when companies both large and small still devotes so much attention to making a fine product not just for mass production but rather to offer the general public something that they will be satisfied with…however I confess being a bit on the more conservative side when comes to my fashion sense of style I’m not sure I could ever picture myself wearing the pair of the red or medium green shoes that are highlighted in your article but to each his own thanks for your hard work and effort in presenting this tour journey for the readers here at Gentlemen Gazette!

P J Weatherby

Hi,

Thank you for a very entertaining and informative post. I live close enough to visit Sanders, and have previously bought on line from them, and wonder if factory tours are open to the general public albeit with the necessary restrictions. Do you know if this is possibe please?

Many thanks

Dear Mr Weatherby,

Of course there are many differences between traditional hand-made shoe-making, as practised by a few specialist firms, and ‘bench-made’ shoes such as those made by Sanders, principally in the lasting, welting and soling operations, which the use of specialist machinery allows to be accomplished much faster (perhaps arguably to a more uniform standard as well).

The quite boldly coloured shoes you mention will not be to everyone’s taste – I have noticed that Tricker’s have gone in for a limited range of shoes from that part of the spectrum also. However, both Sanders and Tricker’s make up for this by producing very many shoes in more sober tones, so there is plenty to choose from – something for everyone.

Dear Mr Hemsley,

I am not aware that Sanders allow visits by the general public, although I may be wrong. Certainly the factory is quite congested and both noisy and hectic, with various potential hazards in the form of fast-moving machinery – it would not be a safe place to take children. I was uneasily aware that my presence there must have been distracting to the employees, although they were uniformly charming and informative about their various jobs there.

Regards,

Christopher Long

Quite informative. The shoes though not really my cup of tea

I really enjoyed reading your article.I love this shoes.

Many thanks, Sergio, I’m pleased you enjoyed it. I am planning to write about more of the Northamptonshire shoe factories soon.

Regards,

Christopher Long