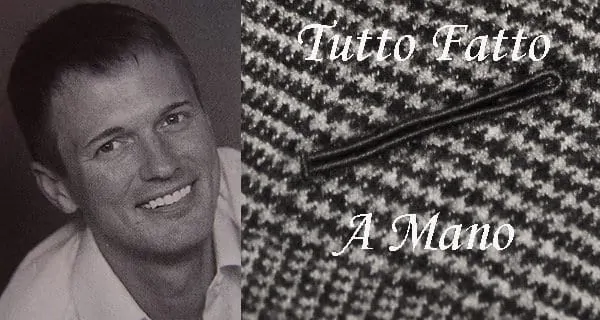

As a regular reader of the Gentleman’s Gazette, chances are you have come across the posts of Jeffery Diduch – aka Jeffery D – who is the mastermind behind the blog about handmade clothes tuttofattoamano.

No matter whether it is the dissection of bespoke suits from Anderson & Sheppard to Caraceni and Oxxford, pagoda shoulder / spalla insellata or the intricacies of handmade buttonholes, Jeffery always provides in-depth articles that are richly illustrated with great photographs. Since I always found these reports very insightful, I wanted to learn more about the author because I thought you could learn a thing or two as well.

Fortunately, Jeffery, the 38 year old Canadian who now works in Chicago was open to my request and happily answered my questions, so let’s dive right in:

Interview

GG: Jeffrey, many clothes enthusiasts know you from your blog but hardly anyone knows how you got into the tailoring trade. Tell us a little bit more about your career.

JD: I started learning to sew when I was very young, and always enjoyed making my own clothes. When I decided to make a career of it, I went to a local private vocational college to get a diploma in haute couture. I started working for a small sportswear company in Montreal, where I did everything from making patterns and markers, to cutting and running garments through the workrooms, as well as packing and shipping. Because we were so small and

I had a hand in almost every part of the business, and it was a really great introduction to the garment trade. At one point, we got an appointment to see the buyers at Saks Fifth Avenue and Barney’s in New York City but I didn’t have anything appropriate to wear, so I bought a neat length of vintage suiting from a local jobber and started to make myself a suit on my lunch hours, entirely by hand. Ladies from some of the surrounding factories would come in at lunch to buy garments wholesale, and some of them noticed what I was doing. They came back the next day with the business card of the factory manager at Samuelsohn, the best suit manufacturer in Canada, which happened to be right around the corner. The factory manager, they said, wanted to meet me, since it was pretty rare to come across young tailors. I went to see him when I got my suit finished, and he offered me a job on the spot. I worked for several years as a factory foreman and learned a lot about the industrialization of traditional tailoring techniques. I later went on to work for a number of the biggest mens clothing manufacturers in Canada and abroad.

GG: Where do you work today and how much of that work is tailoring in the traditional way?

JD: I am currently with W. Diamond Group, which is the manufacturing arm of Hart Schaffner & Marx and Hickey Freeman (formerly Hartmarx and HMX Group). We make a range of garments from fully fused, to half canvas and full canvas, depending on the needs of the retailer.

GG: You worked in Canada as well as in the US – what are the major cultural differences that you encountered?

JD: Canada tends to follow European trends closely, and garments are generally worn much closer to the body than in the U.S., although not quite to the extent that you see in Europe. The U.S., however, has a very rich history in ready-made tailored clothing, having originated the system of the distribution of labor which was later exported to Europe, and many of the styles which go in and out of fashion in other countries are seen as iconic in the U.S. so there is a greater sense of tradition in terms of American styling.

[info]“People have to moderate their expectations with MTM.” – Jeffery Diduch[/info]

GG: As far as I know, you don’t do bespoke tailoring because it is too difficult to make a living. If clients would be willing to pay, let’s say $10,000 for a bespoke suit in standard cloth, would you be willing to work as a bespoke tailor full time?

JD: I enjoy making clothing by hand- even though I have access to the most advanced equipment available in the trade, I prefer to sit and make all of my own suits the old-fashioned way. As a hobby. The money consideration aside, if you are going to pour that many hours of work into a garment, it has to be a garment that you absolutely love; I’ve had clients ask me to make things that I knew I wouldn’t love and I couldn’t do it, so I do this for enjoyment only.

GG: It seems like every day a new MTM suit supplier pops up online. More often than not, the suits don’t fit but they are still advertised as bespoke. What is your opinion this kind of custom clothing and who provides good value for the money in your opinion?

JD: People have to moderate their expectations with MTM. I sometimes see people who expect a $300 self-measured suit to fit perfectly and I wonder how they think that it will come out better than seeing a professional and having multiple fittings and a superbly made suit. Not everyone can afford bespoke, and not everyone has access to stores that offer MTM, so these companies are attempting to fill a hole in the market. But they are certainly not bargain-price bespoke.

GG: What are the most important aspects in a suit for you? Shoulders, pattern, handwork…?

JD: Fit. Above everything else, fit. An inexpensive suit that fits well will always look better than a very expensive one that doesn’t fit; if the suit doesn’t fit, no amount of handwork will make it look right.

GG: When do you consider a suit to be well made? What are the details that you look at in order to determine whether something is a quality garment?

JD: Again, fit is first. If it doesn’t fit right, I don’t care how it’s sewn. And I look at the quality of the execution before specific details. Hand-made buttonholes, for example, can be nice if well done, but if badly done they looked like squashed beetles so I will take a neat machine-made buttonhole over a badly hand-made one any day. Same for most parts of the garment.

GG: I think all readers of the Gentleman’s Gazette agree that fit is most important but I was wondering where you look first in terms of fit – the shoulders, the balance of the coat, the sleevehead etc. can you walk us through the way your eye examines a suit?

JD: When looking at the fit of a coat, first I look at the shoulder, which is the one thing you want to avoid altering if at all possible. If the shoulder fit is off, try a different size or a different model. The fit of the upper part of the sleeve is very important too, since tightness across the back or in the sleeve can create divots which are very difficult or impossible to fix in a finished garment. Then I look how the collar is sitting on the neck, whether there are balance issues like the fronts hiking or the lower back kicking away. I check to make sure the lapels are sitting snugly to the chest and not gaping. Then i will look at the coat waist to see if it is tight or loose, both straightforward fixes. I will look at the pitch of the sleeve and the sleeve length last, which are fairly easy to correct. Jacket length is very subjective.

GG: What is your favorite interlining, and sewing thread for bespoke suits?

JD: My favorite interlinings are from a company called Rovagnati Vincenzo Spa. Their Lana 250 wool canvas is great and versatile, and the Liguria hair cloth is great for the chest and shoulders. I use a variety of different types of thread, depending on the part of the garment, but Gütermann is generally my go-to brand. I’m very fussy about buttonhole and finishing threads, and Gütermann makes some of the best of those, however Amann and Tre Stelle make some very good silk twist which I sometimes prefer, depending on the color.

GG: The hands are among the more important things for tailors. You hurt your hand a few months ago – is everything back to normal?

JD: I had surgery to repair some nerves which were severed in a cooking accident. I regained most of the mobility in my hand, but still can’t feel parts of it; nerve repair can be strange and I was warned that it might not work. I still hope for the best because sewing by hand is very hard when you can’t feel the hand that guides the needle through the underside of the cloth. I end up spearing myself quite badly without noticing. I haven’t been able to do any sewing since the accident and am hoping that will change.

GG: Many tailors are so busy tailoring for others that they rarely look dapper themselves. Do you wear your custom suits or do you prefer a jeans and a polo shirt?

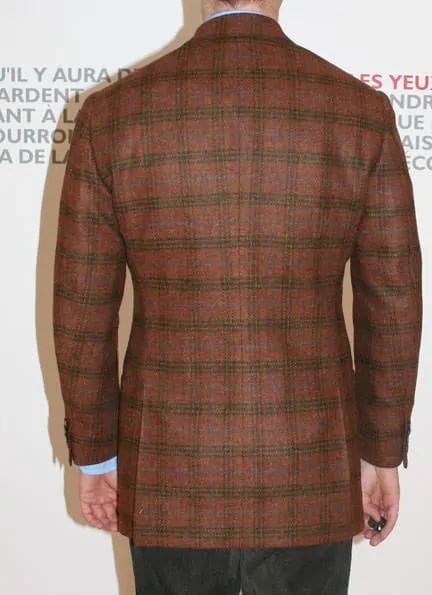

JD: I’m in the tailoring trade because I love tailored clothing- how odd would it be if I only wore jeans and a polo? I’ve made myself about 40 suits and sport coats over the years, and even when going out on weekends I’m usually dressed a little bit more formally than my friends.

GG: That’s fantastic but unusual in my experience.

GG: What are your hobbies?

JD: Other than sewing, I trained as a musician; I sang in an opera chorus and a few early-music ensembles, and until my recent accident played piano.

GG: What do you think about the future of tailored clothing?

JD: We’ve seen a resurgence of interest in it of late, though whether this is a long-term thing or merely a generational anomaly remains to be seen. I remain cautiously hopeful about it.

GG: Lately you have not posted much at tuttofattoamano. What can we expect in the future? More dissections, tutorials etc or are you focusing on something else right now?

JD: The dissections were always meant for clothing nerds to learn something, not just gratuitous violence on tailored clothing, and over the last few years of doing them we’ve exhausted a lot of the subject- there just isn’t very much to see that we haven’t already looked at. They also take a huge amount of time to do- taking the garment apart, photographing, editing the photos, writing up the post… I need an editorial assistant! Also, I have been doing some writing for a few print magazines, like The Rake and some home sewing publications, but I do intend to continue sharing anything interesting that I come across.

GG: Thank you so much Jefferey for your time and for sharing your knowledge! I am sure someone will be more than happy to help you create your insightful posts!

If you are interested in supporting Made by Hand – the great sartorial debate, get in touch with Jeffery.

In case you haven’t already done so, go visit Jeffery’s website and don’t forget to check out the archives on the right.

Remarkable.I love the sports jacket.The gray PoW check will also look nice as suit.

Reference of cloth used would be beneficial.

murtadza

I shall ask him for the cloth, though I am sure you will find the references if you take a look at his blog.

Jeff, what an interesting and insightful interview with this publication! Found it very instructional on tailoring and manufacturing. (I’m Matthew’s godmother. ) I am proud of your talents and best of luck in your future endeavors!

Nice interview, love reading Jeffery’s blog!

Very insightful interview, it’s great to hear advice from someone who has spent years in the trade. I like his take on getting fit right before everything else, including materials and button holes. Getting fit right across the shoulders, the upper arms and back seem to be the most critical components as most other measurements can be adjusted after the fact. Nice advice.