Since 1890, Edward Green has championed a higher quality English footwear with finer details than the rest of the market or, at least, if you believe their marketing. Today, we’ll figure out if that’s actually the case by looking at the history of Edward Green, cutting apart a pair of Edward Green shoes, looking at the materials, construction and styling, lasts, widths, and tell you if it’s worth $1250 to $750 or not.

Edward Green Shoe History

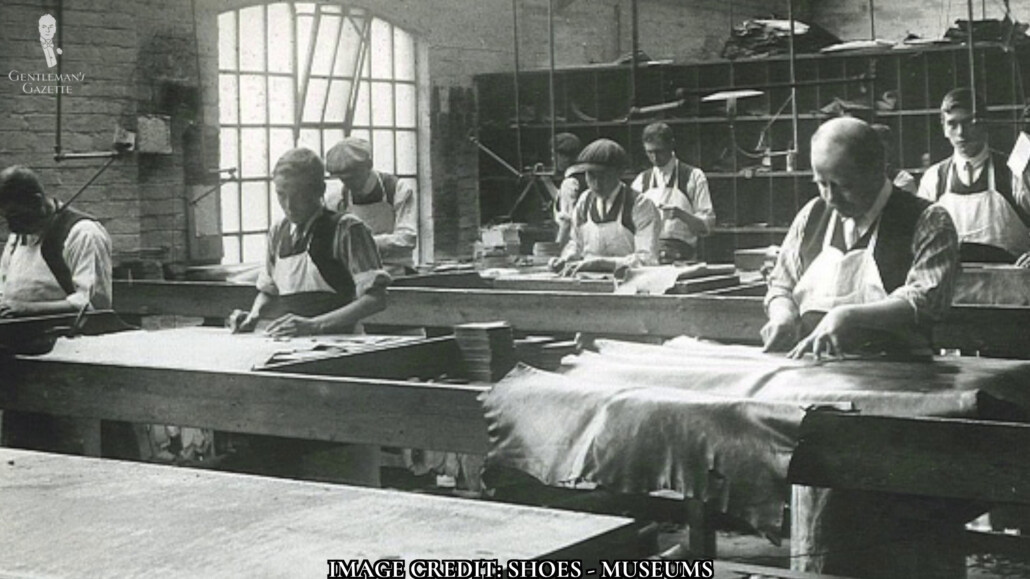

First up, Edward Green shoes are made in Northampton, the men’s dress shoe capital of Great Britain; some may argue the world. The town’s rich shoemaking heritage was long established before Edward Green.

In fact, it hits back to the late Saxon period. In 1213, King John ordered a pair of riding boots for nine pence, which may be the equivalent of 37 pounds. But, I don’t know if you can calculate inflation over more than 800 years.

There are also records indicating that, by 1356, there were shoemakers’ and tanners’ guilds in the town of Northampton. As a resident of Northampton, it was somewhat foreseeable that young Edward Green, at the age of 12, joined the shoemaking trade. First, he started as an apprentice clicker.

What’s a clicker, you might ask? That is actually the person who cuts the leather and, when you remove the knife from the leather, makes a clicking sound – hence, the term “clicker.”

Through his training cutting the various parts of the uppers and the lining of shoes, he learned a lot about quality and what to look for not just in the finished pair of goods but also in the materials that make up a shoe.

As he grew more skilled in his role, he realized there was a market pitch for higher-quality shoes. At a time, as a result of the second Industrial Revolution, there had been more of a trend toward mass production. It was Green’s desire, though, to preserve the values of excellence that he felt people deserved. So, driven by the ambition to produce higher-quality footwear than what was available at the market, he started his own workshop in 1890 in Northampton.

Not only did he set about to recruit some of the most illustrious craftsmen for shoemaking in Northampton but, because of his training, he also knew where to find the best materials. Knowing that he was an expert in each field of shoemaking, he wasn’t afraid to promise excellence without compromise.

Turns out, that phrase resonated with a clientele that enjoyed high levels of craftsmanship and luxury shoes. As with so many industries, during the Second World War, Edward Green became one of the largest producers of British officers’ boots in the 1930s.

After the war, they returned back from boots, focusing more on traditional men’s dress shoes. These were met with a claim by icons like Ernest Hemingway, Cole Porter, or Edward – this time the Duke of Windsor.

In 1977, Edward Green’s nephew, Michael Green, sold the company to an American. His name was Marley Hodgson, and he was in leather goods. But, nevertheless, the company experienced some financial difficulties by 1982, which prompted another sale.

The Czechoslovakian native John Hlustik bought it for a symbolic one British pound. You can’t even get fish and chips for them anymore. Hlustik was a bespoke shoemaker who had trained in Italy and Spain and liked that cachet excellence of Edward Green. He fearlessly wanted to return to the promise of “excellence without compromise.” It was he who introduced the antiquing and burnishing processes that Edward Green is famous for today.

He’s also credited with the way British men thought about their shoes. John put a strong emphasis on wearing brown shoes rather than black Oxfords. Why? Well, even a very dark pair of brown shoes typically shows the true character of the leather with its patinas and hand-burnished effects much better than a pair of solid black shoes.

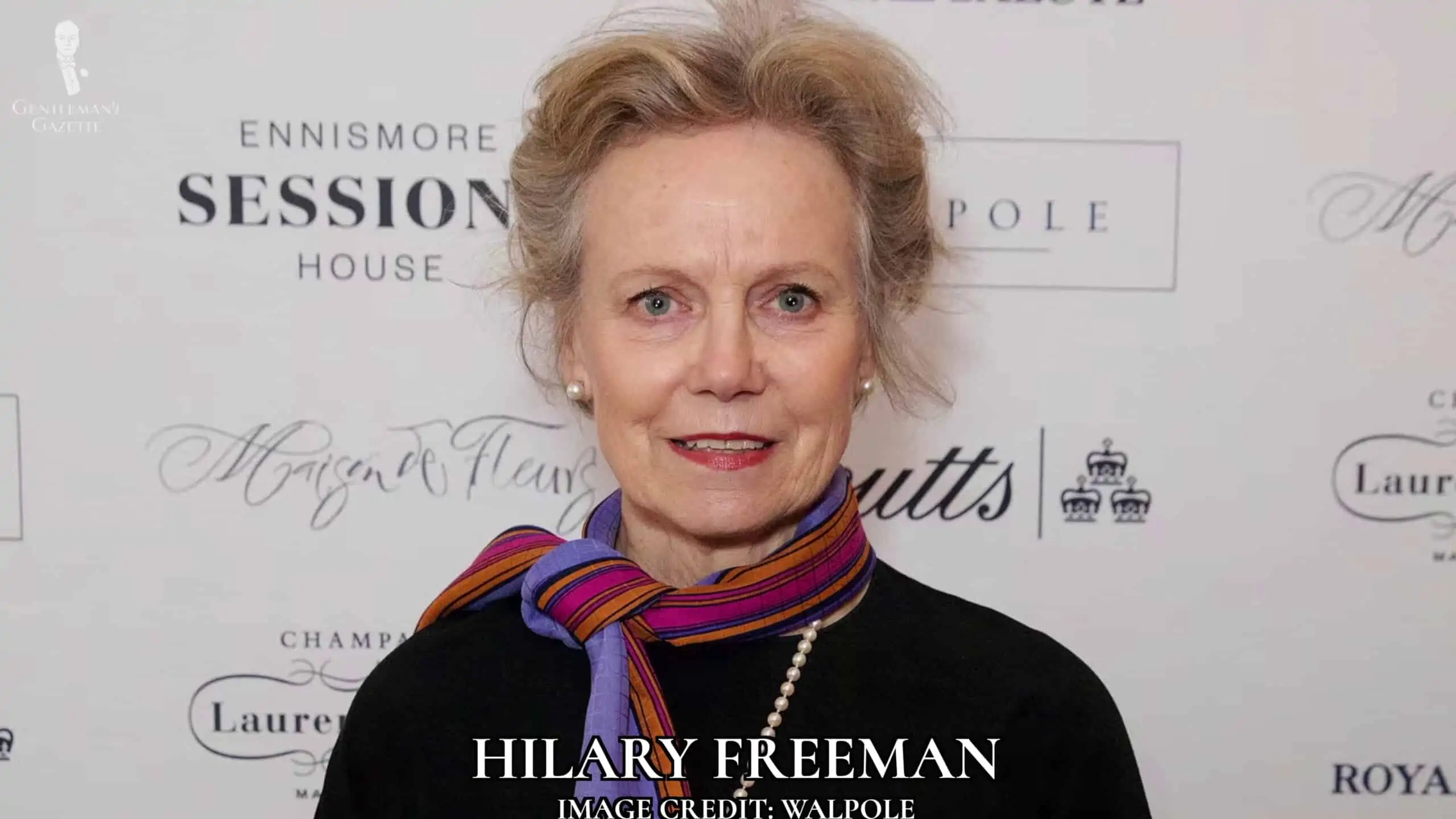

When Hlustik suddenly passed away in 2000, the company was continued by his partner Hilary Freeman. Making good on an expansion that Hlustik had already started, they moved in 2004 from two tiny buildings to a more aerial space on Cliftonville Road, which they now call home.

This factory houses over 60 skilled artisans. Among them, until 2006, was Tony Gaziano, who spearheaded Edward Green’s bespoke shoe department. Of course, by then, he teamed up with fellow shoemaker, Dean Girling, to found Gaziano & Girling and went his own ways.

Edward Green Today

Upon Tony’s departure, Edward Green decided to no longer offer bespoke shoes, but rather move to a made-to-order program. Today, their shoes can be ordered from over 60 stockists along with a line of ready-to-wear shoes. No matter if you’re in London, Paris, New York, or Tokyo, you can find a pair of Edward Green shoes.

Today, Edward Green is considered a smaller manufacturer of high-end dress shoes; only making about 325 to 350 pairs a week. That may sound much, but compared to let’s say Crockett & Jones, who put out 2,000 pairs a week, it’s just a small part.

Materials

In terms of the materials that Edward Green uses, they pride themselves in using the finest European calf hides that are then burnished and antiqued by the artisans. Of course, they also use other types of leathers such as cordovan, patent leather, or velvet for slippers. However, the majority of their shoes are either finished in burnished calfskin or suede.

For the most part, their leathers are sourced from Haas Tannery, a French tannery that has been around since 1842 – also supplying leathers to other luxury makers like Hermes. Apparently, their suedes mostly come from Italy, but who knows these days, it’s very easy to change leather manufacturers for shoemakers.

On their website, they don’t really go into detail and what they use for the sole leather. They only mention it’s oak bark tanned, and that is definitely good because it makes for a quality, long-lasting soles. Otherwise, they have a range of rubber soles, ranging from R3 or Dainite to Ridgeway.

Manufacture

So, of course, for an expensive product, a big question is always: How is the quality and the level of craftsmanship of the shoe?

Apart from using high-quality materials, the leather uppers are hand-clicked, which means they’re cut by hand. That doesn’t mean that someone uses a knife necessarily and cuts out everything individually, but they use the shapes, look at the hides, look at the skins, and place it in a way to avoid any imperfections and get the best part of the skin.

The process not only takes more time, but it also creates more waste, therefore, resulting in an overall higher price than compared to the manufacturer, who just goes for maximum yield of every skin. The shoe is closed or stitched together by skilled sewers with a sewing machine.

“Handmade” is not a protected term, and when it comes to fine handmade garments, people (especially clothes enthusiasts) often frown upon the use of a machine in the process. For shoes, using a machine and handmade go hand-in-hand because it requires a lot of skill, and the result of using a machine is much superior than if you would stitch uppers together just by hand.

Additional details such as broguing are also done by a machine on a wheel because it’s much more efficient than if a bespoke shoemaker punches out each hole individually. Of course, the advantage of punching out every single broguing hole allows you to use diamonds instead of rounds maybe and place them in a certain way in corners, which is not something you can do if you do the broguing on a wheel.

Edward Green also attaches the upper leathers to the last with the combination by hand and machine, thus allowing for correction, so everything looks perfectly aligned and you have fewer seconds.

In theory, you could argue that this hand finishing process results into a tighter, more structured waist, but if you compare it to other shoes like the Linea Maestro from Meermin, which was the number one shoe in our best shoe ranking under $300. You can see they’re fairly similar.

The majority of their shoes are Goodyear welted; I think only some of their Albert slippers are not. But the lion’s share is Goodyear welted on a machine. They use a leather insole, not any leather fibers. It’s not cheap stuff. The gem band is then glued on. They add a very thick layer of cork to the inside, which is thicker than what we see in Allen Edmonds, for example, or in other makers.

Myth or Magic: Are Goodyear Welted Dress Shoes Overrated?

It is, however, the same cork filler material that you typically find in shoe factories. It is not the solid cork that a bespoke shoemaker would use because it takes more time and is more costly. Between the cork layer and the oak tanned leather outsole, you’ll find a wooden shank so that the metal detector won’t go off at the airport.

Also, between the shank and the outsole in the waist area, you have an additional piece of skived leather that helps create an elegant beveled waist on every pair of Edward Green shoes. The welts and clothes channel soles are also sold by machine and, yes, this can be made by hand. But, it’s typically only something you’ll find in a bespoke shoe.

By the way, if you want to learn how a pair of bespoke shoes are made from start to finish by one skilled shoemaker, check out our in-depth series.

Compared to an Allen Edmonds shoe, the sole of an Edward Green shoe is very refined. But, if you compare it to, a Gaziano & Girling shoe, I think they’re even more elevated than the Edward Green shoes. Yes, they all have that slight bevel through the additional piece of leather. But, frankly, that’s nothing really special anymore these days.

Construction

Taking a closer look at the construction of the shoe, a few things stand out. First up, the uppers are all very neatly sewn – they’re either backed with fabric when it comes to broguing, or with an extra piece of leather. The toe cap on the Edward Green shoe we cut apart was made of thermoplastic on the 888 last.

Interestingly, something I hadn’t seen in any other factory-made shoe was reinforced leather parts on the left and right of the uppers that stretched from that front cap all the way back to the heel cap, which was made of a stiffer leather. So, back was made of stiff leather, front out of a thermoplastic, and, in between, layers of a softer leather.

On the inside, then, you had a leather lining. In the front part of the foot, it seems to be a veg tan, undyed leather. The back part has the same lining color as the uppers, which makes it very consistent.

As with all other Green shoes, you always see their little size label, which is oval, and it has half sizes in there, which are typically the UK size and a US size. Some people argue, though, that depending on the last, sizes fluctuate, so it just helps you to find roughly the right shoe for you. Otherwise, their heel is made of layers of leather.

The corners are not cut off like an Allen Edmonds shoe, but I’ve not found that it interferes with my cuffs or turnups on pants. There are actually quite a few nails in the heel, so it was a little harder to take apart. When they actually put the uppers onto the last, they use these little tags that we’ve seen in many other ready-to-wear shoes as well. It’s a very common process. Sometimes, you also see a bit of plastic in there, but that is not bad. It just comes from the protective layer on top of the uppers, which is applied to not damage the uppers during the production process of the shoe. Otherwise, there is a half insole on top of the insole in the back with a little foam pad underneath.

The tongue is just lined with leather – there’s no additional padding there – and, personally, I’m not a big fan of those half soles because, over time, when you get in and out with your foot, it becomes loose because the glue doesn’t keep the leather all the way down. I personally prefer no insole liner at all or a liner that goes all the way. These half-liners are just half-assed in my mind.

Last but not least, they have a little rubber heel part, which makes perfect sense because it extends the longevity of the shoe compared to just being all leather. Last but not least, the final color of the shoe is achieved by antiquing and burnishing in the factory, so you see that slight inconsistency throughout the shoe, which is beautiful and creates a better depth of color.

Anatomy of a Dress Shoe

While, today, many shoemakers offer this level or even a higher level of customized patinas on their shoes, Edward Green was definitely the forefather in the English industry for that kind of look.

It’s not on the level of Gaziano & Girling, who literally give you a fully mirror polished shoe every time you order a pair from them, but it’s above the general shoe that you get when factories just finish it at the buffing machine.

So, today, in terms of construction, Edward Green is certainly between an A- and a B+ because it’s more like a bespoke shoe than other factory shoes. But, it’s not fully there. Of course, even the best construction is worthless if the last is really ugly.

Lasts

In our minds, the look of Edward Green’s lasts can be summed up in two words: “quintessentially English.” Throughout the range, you see this tendency towards understated classics that are not boring or out-of-proportion. There’s no fussy detailing that you may find in another English brand by the name of Jeffrey-West, for example.

Of course, they’ve had many different lasts throughout the years. For example, this softer, chiseled 888 last – it’s very popular. They also have the almond-toed 82 last or the more round 202 last. Somewhere in the middle is the 184 last, which is Edward Green’s loafer last.

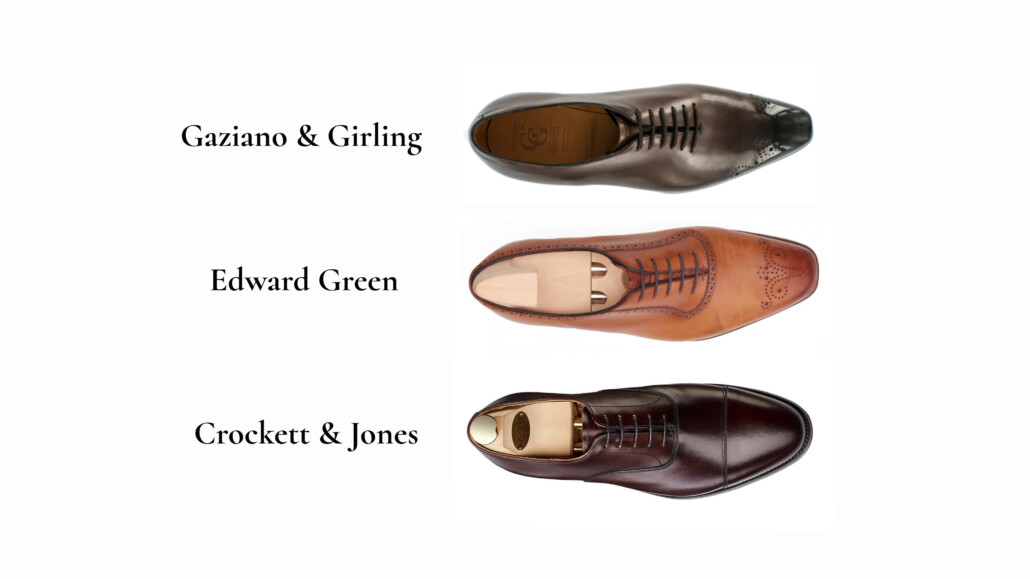

Overall, I would say their last design is maybe in between Crockett & Jones and Gaziano & Girling. If you compare them, you can see Gaziano & Girling is more extreme, more streamlined. Green’s a little more subtle. And then, maybe Crockett & Jones a bit more round; not as refined on a chisel. But, by no means are they chiseled like a George Cleverley bespoke shoe, for example. The round 202 last, though, is also not bulky like a round last from the Grenson 301 last, for example. Edward Green always goes for a somewhat elegant, middle-of-the-road design.

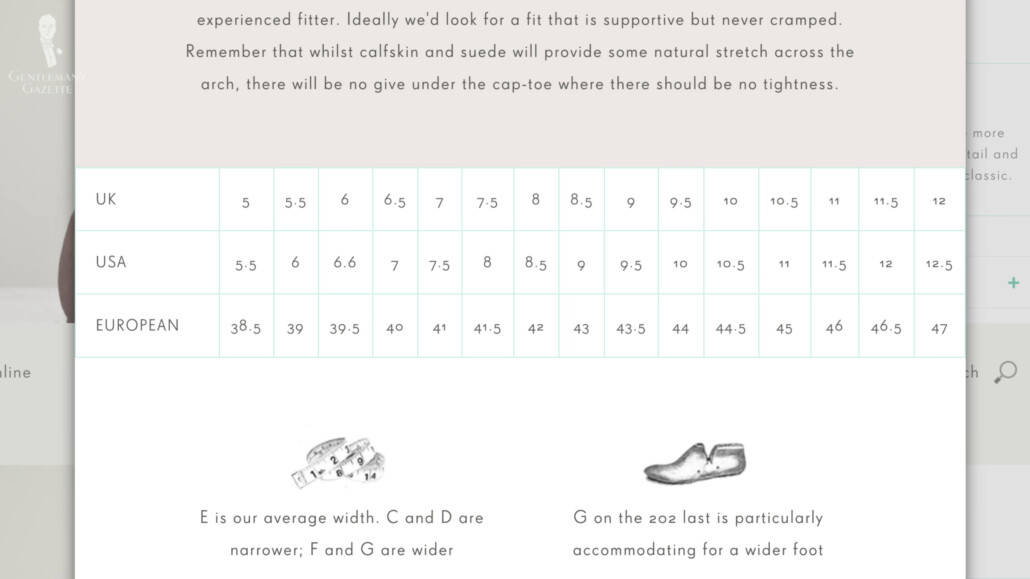

The company also recommends getting your feet measured, and that’s for good reason. They actually have four different widths in their last, which is really nice to find something that actually fits your foot well without going bespoke.

Of course, the shoe size always varies with the last, so they always have the UK size and US size in there. And sometimes the shoe turns out a little larger, a little smaller. So, you know that maybe you have a size 10 UK in a 888 last, but you need a 10 and a half in the 184 last. Of course, having a large range of widths and sizes means you have a large number of stocks to handle, which typically increases the price of the product.

12 Essential Tips to Get the Best Shoe Fit

I’d say the majority of the ready-to-wear collection is available in an e-width. Let’s say if you buy a shoe online, that’s likely what you’ll get. But, you can always have a pair specifically made in the width you want for no extra upcharge. You just have to wait.

Styles

In terms of styling, the Edward Green styles are very similar to the lasts – pretty classic without much “shebang.” The four most notable ones are probably their cap toe Oxford, Chelsea style, then they have their Piccadilly loafer, which is a round toe penny loafer, or a split toe Norwegian derby called “Dover.” It has a hand-sewn apron done with a boar bristle that gets exactly the right tension on the upper. But, of course, it’s more time-consuming to make. Therefore, the price is a little higher. These typically come in at $1600 – $1700. They also offer a derby boot, which has been in production since the 1930s.

And with those four styles, which also make a good initial four shoe or boot collection, you cover quite a wide range. But, if you’re interested in more unusual styles, then you usually have to go with a made-to-order program.

Personally, I’m a big fan of their two-tone loafers or their canvas spectators. Not something you’ll find with other manufacturers typically. They also have tassel loafers, monk straps, double monk straps, Chelsea boots, and so forth.

If you want something sleeker, they have whole cuts or something more casual like a chukka boot or something in between like a derby boot with a hand-sewn apron.

Is It Worth It?

So, now that we covered the history, materials, craftsmanship, and style, the big question is: are Edward Green shoes worth it or not?

Frankly, no matter where you’re in your style journey, spending $1,250 to $1,750 for a pair of ready-to-wear shoes is simply a lot of money.

Let’s look at the pros and cons. I think the workmanship of the uppers, the way it’s lasted, the reinforcements, and the materials themselves are top-notch. Of course, we’re talking about ready-to-wear shoes. It’s not top-notch if you compare it to a bespoke shoe. I think I can see and feel different compared to, let’s say, a Carmina or a Crockett & Jones or Allen Edmonds, for example. The latter is softer, more supple, and also the patina is really nice.

It’s also better than John Lobb. By the way, if you want to learn if they’re worth their money, check out our review on their shoes, as well.

I’d also say their shoes require less of a break-in period than a pair of Allen Edmonds; for example, everything seems to be a tad softer and more supple.

Another pro is their large range of widths and sizes as well as their refurbishment or refractory program. For example, one of our team members, Jack, had his shoes re-lasted and remade at the Edward Green factory. He had bought the shoes originally in the wrong width, and he used our secret process of finding a great pair of shoes at a low price, which you can find here.

Vintage Menswear: 25 Tips & Tricks for Thrift Store Shopping

He scored on eBay, but realized they were all wide, but he liked them so much, he wanted to keep them. So, when he had them factory re-lasted, they agreed to put it on a slimmer last, and now, the shoe fits much better than when he had it originally.

This all costs about £275 or, at today’s exchange rate, about $335. Other manufacturers like Allen Edmonds also offer a resoling program. But, that you’re able as a customer to choose a different last is pretty unheard of. I’m not saying it’s not possible. It’s just not common. So, props to Edward Green for doing it.

Frankly, the only beef I have with Edward Green is probably with a heel. It’s a fine heel. It’s made of leather, but it’s not shaped in a particularly elegant way. It’s also a little low for my taste. Typically, bespoke shoes or higher-end shoes have a slightly elevated heel that is maybe a little more narrowed down, And sometimes, you see their bespoke shoes, they have more of a Cuban heel. That’s not something you’ll find on this shoe, and it’s not something you typically can find on any factory shoe, for that matter.

Edward Green is also not just any factory shoe. It’s probably one of the most highest-priced factory shoes out there. Compared to Gaziano & Girling, Edward Green is styled less extremely, it doesn’t come in as nice a patina, and the shoes are more expensive than Gaziano & Girling.

That being said, not everyone is a fan of Gaziano & Girling because it’s maybe too much for them. On the flip side, a lot of shoe enthusiasts really like the Gaziano & Girling styling, but it’s ultimately very subjective and up to you. And there’s no real pro and con that I can tell you. It’s something you’ll have to figure out yourself.

In my mind, by far, the biggest con of Edward Green shoes is the extremely high price. I mean, I get it. They have a dealer network. They produce in England. They take more time. Labor costs are higher. Everything is more expensive. They want to position them up-market, so they probably intentionally yank up the price. And all the vendors and stockists have to make money, too. But, from a consumer point of view, I find that, despite the really high level of quality, all the reinforcements, and all that workmanship and craftsmanship you get, it’s still a whole lot to ask.

So, in my mind, Edward Green is only worth it if you can buy it on a steep sale. For full retail price, it is not worth it, in my book, and I’d rather buy five pairs of Linea Maestro from Meermin than one pair of Edward Green at retail price. If you like the Edward Green styling, I also urge you to consider George Cleverley ready-to-wear, which is somewhat similar in styling – very British but considerably less expensive.

That being said, brands like Ralph Lauren Purple Label have used Edward Green to make private label shoes. If you can find them at a discount or if you find them elsewhere, I think Edward Green is a great buy, especially if they fit you and you can find the last that works for your foot.

For $1,700 or more, you can also start finding bespoke shoemakers in Italy, sometimes in the US. Of course, they’re not the big names. They’re smaller shoemakers. But, you get a level of craftsmanship and customization that you cannot get from a factory shoe.

If you want to go a step down, there are also certain remote bespoke programs that are made in Asia, such as Wayman Bespoke. And there, we’re talking about maybe $1,100 as a starting price for bespoke shoes, which is a lot less expensive than what you get from Edward Green. Of course, you may not get the exact styling, you may not get the same level of patina and burnishing, but it all depends on the bespoke shoemaker.

Overall, it takes a lot more time from you, and it’s a different project. It’s like comparing apples to pears. Bespoke shoes are very different and appeal to a different market than ready-to-wear shoes. I just want to throw it out there because when you’re spending so much on a ready-to-wear shoe, it’s good to know what the alternatives are.

What’s your opinion? Do you have a pair of Edward Green shoes, or did we inspire you to buy one? Please share with us in the comments.

Outfit Rundown

The shirt I’m wearing is a linen shirt from Spier & Mackay, which we made a review about here.

My pants are a silk-linen blend from Polo Ralph Lauren. They come in a very light summer weight, and I really like them.

My socks are from Fort Belvedere. They’re navy blue and white, two-tone solids, and they pick up the color scheme of the rest of the outfit.

My shoes are Oxfords from Edward Green on a 202 last in a dark chocolate brown. I paired them with a brown belt from Fort Belvedere and a gold belt buckle from our belt system.

I have a little pinky ring with a nice, light green jade stone, and I typically wear that with a jacket.

In this case, this is an Isaia jacket. It’s a herringbone jacket, blended fabric with peak lapels, a high buttoning point, and I’m combining it with a white boutonniere that has some green to pick up the color of the ring, which you can find in our shop here. Just like the pocket square, which is printed English silk in tones of brown and blue.

Just a FYI often the word leathers had been replaced (probably by autocorrect) with letters

as always very informative

Thanks for the heads-up, Gordon! I think we’ve managed to sort our letters from our leathers now :)

I find it funny that today I’ve received my first Edward Green’s pair of shoes (Belgravia loafers + EG shoe trees) and you posted new post/video as well.

Very interesting reading – know much more about the brand now.

Going tomorrow to the service to add Triump metal caps as well as rubber grip, so I’ll be able to wear it even in wet autumn. :)

Fantastic! I certainly hope you enjoy your first pair of Edward Green shoes. Excellent choice, by the way – I’m also quite fond of the Piccadilly loafers as an alternative choice.

Thank you Jack!

Personally, I am looking for a Harrow penny loafers from Edward Green. They are unlined – something I would really like to try as summer shoes.

Very nice, Dmitriy! Although not an Edward Green model, I own a pair of unlined Belgian loafers for summer wear. In my opinion, suede is a wonderful choice here, as it feels so soft and light as an unlined. But even an unlined calf is a lovely thing when the temperature rises, as (at least, for me) the cooler wear comes from the overall reduced weight and structure in the shoe.

Sirs

I bought two pairs of Edward Green Galway boots, one pair in Rosewood and the other pair in tan.

Both lovely boots and I was happy with them at the start, but….. after a few wears they started to hurt my feet just behind the little toe area.

I rang Edward Green and explained the problem and they said to send them to the factory and they would stretch them. I decided to take them in myself, living in Milton Keynes, I’m just 20 or so miles away.

I was introduced to a guy called Carlos Iaconianni who was more than helpful, I had to go back and have them stretched some three times and now and after that both pairs are now absolutely perfect.

Once again, Carlos was so much more than helpful, they were pricey but I love ’em!

Full marks to Edward Green.

Excellent to hear your experiences about Edward Green, Bob. In the world of fine footwear, the after-sales processes are rarely discussed, because so few ready-to-wear makers offer them. It’s why we included my own experiences with similar shoe stretching services in the article/video.

Cleverley rtw is made by C&J to their handgrade standards.

I don’t think the Piccadilly loafer has a split toe?

Nice spot, thanks, Graham. It seems that we just had a double-up of the term in the script, so although the video states the Piccadilly is a split-toe, the article has been updated to reflect that it is, in fact, not a split-toe loafer.